The Striker battle dress uniform was radically overhauled in 2012. Since then, it has led the industry in reliability, functionality, and comfort. In this blog post, we discuss the major changes and adaptations made to our Striker XT Gen.2 BDU in order for it to become what it is today.

In this blog post:

BDU requirements

Let's start off with some basic thoughts about what operators look for in a battle dress uniform.

To meet the needs of operators in the tactical space, a high-end BDU must successfully address three key considerations:

- Weight

- Functionality

- Durability (i.e., it must withstand friction generated by externally carried gear continually rubbing up against it)

Our own BDU successfully addresses all three considerations, as you’ll see in this article—a review of the evolution of the revolutionary Striker BDU.

Milestones

Striker Combat Pants (2012)

Striker Combat Pants were the first product to emerge from our planned battle dress uniform lineup.

The initial design of these pants addressed two central issues faced by BDU wearers.

First, the area of the upper thigh invariably heats up whenever one engages in physical activity such as marching or (especially) stepping up the pace to double-time or just flat-out running. Being one of the largest muscle sets in the human body, the activated upper thigh generates much heat.

To deal with that issue, we devised a most reasonable solution. It was to make the front and back of the upper-thigh area extremely air permeable. We achieved this by employing a unique knitted nylon-cotton (NyCo) blended fabric.

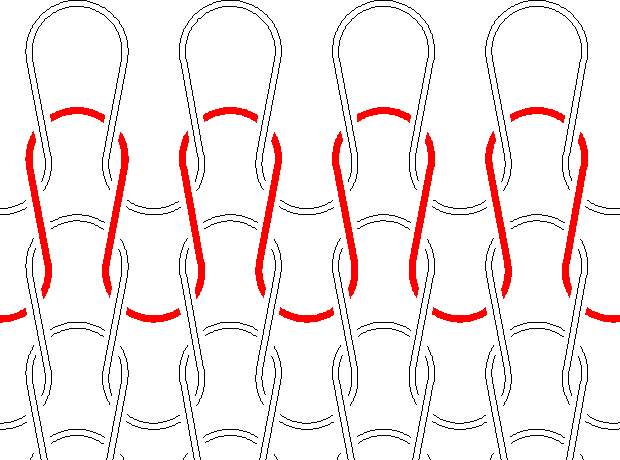

A typical knit schematic. Image source: CC BY-SA 3.0, Wikipedia.com

This fabric offered high-temperature ventilation performance that was unmatched by any material we had up to that time evaluated.

Unfortunately, this material wasn't widely adopted in the tactical space. The reason had to do with durability—or, to be more exact, a lack of durability. The knit structure was found to break easily. All that was necessary to trigger breakage was the failure of but a single yarn in the weave (as shown by the red yarn highlighted in the image above).

During manufacture, the strong forces exerted on the fabric by the production machinery could be enough to leave the material structurally damaged right out of the factory. This was a quality control issue that affected very few pants. But it was enough of a concern to us from the standpoint of quality standards that we excluded this specific version from future designs.

A second central issue addressed by the initial design called for use of Tourniquet TQ loops in the upper thighs. It was thought at first that this would enhance the practicality of the pants. However, the experience of operators in the field suggested otherwise.

One more thing: side pockets had a slightly different shape compared to the modern Striker XT and there was no phone pocket with retention strap.

One of the early prototypes of the Striker XT Combat Pants (left) side-by-side with standard Striker Combat Pants (right).

Striker XT Combat Pants (2014)

The changes made to the XT iteration of this model were significant and represented a solid foundation still reflected in the products we know today (indeed, they provided a basis for the “Gen.0” series to come).

One of the changes entailed cutting the pants to give them more of an anatomic fit. We accomplished this by increasing the stretchable area in the back.

Also, we sewed the back pockets to this stretch fabric, which allowed for the unicolour area to be broken up with camouflage elements.

Further, the waist was positioned higher. This enhanced the fit, but as well allowed the wearer to engage in a wider and freer range of movement.

The knees were given a more ergonomic shape. We did this by implementing two schoeller stretch areas below and above the knees. This configuration allowed legs to be spread apart farther while at the same time providing better protection.

Added too was a separate pocket at the knees to contain UF PRO Solid Pads. This innovation let wearers simply insert rather than strap into position penetration-resistant pads.

Another new feature was a double-fly zipper (meaning, it can be zipped from below or above). Similarly, we incorporated zippers to allow the wearer to adjust leg width as needed for a better fit around boots.

Evolution of the Knee Section

In the span between the Gen.0 and Striker XT Combat Pants, a full overhaul of the knee section took place. This represented one of more significant changes to our pants design.

The idea was to separate the Solid Pads and our CUSHION/IMPACT knee-protection pads in order to give operators the benefits of modularity in a BDU.

Perhaps the most interesting prototype to emerge from this development process was the “striped” knee version. It used a mix of the same stretch material found at the back of the pants plus CORDURA fabric.

We experimented with CORDURA, stretch, and ripstop combinations, all dictated by the Solid Pads that shaped the knee section.

In the end, the deciding factors were penetration resistance, durability, and comfort. CORDURA was the easiest overall option for the knee section thanks to its durability and availability in camouflage colours. The alternative—schoeller®-keprotec—was great in terms of performance, but lacked IR protection and camouflage options.

The knee pads themselves were subject to redesign a bit later. The first line of improvement was the material used in the pads.

The first material version used was a d3o version, which was later dropped because of durability and weight concerns.

After the initial version, we switched to SAS-TEC material (still in use today in our pads for elbows as well as knees). We liked that SAS-TEC was available in two versions. One was a super-soft foam that was optimal for additional cushioning. The other, which became our go-to choice, was meant for impact protection owing to its excellent energy absorption properties (the pads stiffen upon impact).

These two materials became what is known today as the IMPACT and CUSHION versions of our 3D Tactical Knee Pads.

The next big step involved altering the actual shape of the knee pads. We found that creating a three-dimensional shape (as opposed to the conventional flat design) allowed us to shave off some weight and improve the pads’ ergonomic fit by mimicking the vertical and horizontal flex of the human knee itself.

The new shape also allowed us to reduce the thickness on the edges of the pads (about 5mm) and shift it to the middle (6 to 7mm) where contact with hard surfaces or protruding objects is most likely to occur.

As a bonus, the curvature of the new shape also provided better vertical movability.

The new design of the 3D Tactical Knee Pads also included a separate Solid Pad pocket. This design allowed operators wearing pants from our P-40 Tactical Pants lineup to benefit from using penetration protection.

Striker XT Gen.2 Combat Pants (2016)

The Striker XT Gen.2 is our current UF PRO benchmark for an overall best-in-class pair of combat pants.

The two massive overhauls of the Striker Combat Pants and Striker XT Combat Pants carried over to the Gen.2, while the waist and knees remained the same.

The main differences are the Gen.2’s pockets on the back stretch area and their incorporation into the stretch area. This allowed us to provide a much larger stretch surface, the result being better comfort.

Two additions which not present on the Gen.1 were:

- lower leg drawcord regulation (the string was incorporated into the lower leg pocket);

- boot hooks (devices that allow pants to be secured over boots and prevent the infiltration of sand, mud, snow, and other undesirable materials).

Striker HT Combat Pants (2015)

Striker HT pants were released a year before the Striker XT Gen.2 model.

The design of the HT replicates that of the XT Gen.2. The big difference between the two models was the HT’s implementation of front ventilation zippers—two of them to be exact—to permit adjustment of the amount of air capable of flowing inside the pants. These zippers were designed to work as an all-round pair, similar to those built into the XT Gen.2 model but with the inclusion of a feature for use in higher temperature environments.

Striker X Combat Pants (2019)

Striker X Combat Pants were the most recent addition to the lineup—and the first designed to meet the needs of a specific tactical sector.

The inputs required to design so finely targeted a pair of pants came from military operatives whose opinions and ideas we solicited. It was thanks to their feedback that we were able to build from the ground up combat pants expressly tailored for use by military operatives.

The X model featured construction streamlining—a major departure from the past. We took out the external Solid Pads pocket at the knees, and throughout the garment we overlapped its seams by using a special technique to reduce the risk of the pants ripping if snagged by tree branches or barbed wire.

The military operators told us they wanted pants that—in the event of damage—would be easier to repair in the field. Their wish was our command. To facilitate easier repair, we employed buttons instead of zippers for pocket closure mechanisms. We also made certain design choices that allowed the pants to be restitched with just needle and thread (as opposed to an industrial sewing machine).

Get more intel about the Striker X Combat Pants here.

Striker XT and XT Gen.2 Combat Shirt (2016)

With any combat shirt, there’s a battle between comfort and durability. It’s one contest where you find yourself rooting for both sides to win. Which would be possible if the material from which the shirt is made can be:

- quick drying thanks to fast transport of body moisture;

- highly durable;

- supremely comfortable.

Unfortunately, in 2016, there wasn’t available a material to permit those three properties to coexist in equal measure. You could have all three in one material, but only with compromises.

Image of the Striker XT Combat Shirt

The overall design of the Striker XT “Gen.1” Combat Shirt was good. But we wanted more than good. We wanted excellence. And the shirt received a huge push in the direction of excellence with our introduction of the Gen.2.

Among the improvements made to the Gen.2 was the placement of weight distribution air/pac inserts in the shoulders.

The Striker XT Gen.2 Combat Shirt.

We found that the material we had used in the armpits lacked adequate antibacterial properties. As a result, the shirt tended to develop an obstinate odour after prolonged wear. We remedied this by replacing the original material with a Merino wool fabric. To increase the wool’s durability, we also overlaid it with a high-strength polyamide net.

Another change—a relatively minor but nonetheless useful one—was the addition of a bite-in strap as an opener of the pocket built into the upper sleeves. We determined this would simplify usage by operators.

More functionality was achieved by adding Molle channels to permit the placement of gear on the lower sleeves and by incorporating an accompanying device pouch. Interestingly, the device pouch was originally intended as a super-convenient place to stow smartphones and other digital mobile devices (along with maps and pens), but the tactical industry went in another direction on that and so we discontinued this particular feature.

Get the UF PRO Striker BDU

Gear up with the latest in Striker gear here.