NyCo (nylon-cotton blend) is a material commonly used in the manufacture of tactical gear. What makes it so well-suited to this application is the combining of the best that each of the two base fibres offers. Nylon brings to the mix its great durability and more, while cotton brings comfort plus other excellent qualities.

In this blog post:

Introduction

If you’ve been in the tactical field for a while, you’ve probably at some point encountered a NyCo fabric. No big surprise, since this material features excellent performance characteristics making it ideal for military and law-enforcement gear.

NyCo brings together the best of the two fabrics from which it is blended—nylon and cotton. Nylon gives it tremendous durability. Cotton gives it exceptional comfort.

About NyCo (nylon-cotton)

A brief history of NyCo

In the last century and even to this day, nylon and cotton were/are two of the most extensively used fabrics in the clothing industry (polyester comes in third).

Nylon is a synthetic fabric. It emerged as an important material in the tactical apparel and tactical gear industries just before World War II. Riding nylon to the post position in the race to the top was the DuPont chemical company.

The war years saw nylon begin to challenge cotton for supremacy as the preferred material for garments and other gear. Even so, synthetic fibres like nylon had a long way to go to reach the top. In those days, nylon’s share of the market stood at a mere 15 percent or so.

Synthetics gained ground slowly but surely in the postwar era. By the 1960s, nylon (together with the synthetic fibre polyester and a few similar others) accounted for more than 50 percent of the market for not just tactical gear and apparel but for all categories of clothing.

PolyCo (left) and NyCo (right) Striker X Combat Pants.

The exact date when the first NyCo fabric debuted is hard to pinpoint. However, we can say with certainty that it was invented sometime during the second half of the last century.

NyCo fabrics are predominantly manufactured and used in North America and Asia (whereas in Europe, polyester-cotton (PolyCo) blends are king and have been for the last 50 years).

As recently as a decade ago, NyCo fabrics were extremely difficult to come by in Europe. But even though they now are available in abundance, European military and law-enforcement organizations continue to maintain their now firmly entrenched tradition of using PolyCo in the manufacture of their combat uniforms and BDUs.

Quick Facts about NyCO

What is NyCo fabric?

NyCo is an abbreviation for materials blended from nylon and cotton. NyCo boasts the excellent abrasion-resistance properties of nylon and most of the performance characteristics of cotton, including comfort and moisture retention.

Is NyCo Flame Resistant?

No. NyCo fabrics are neither flame-resistant nor flame retardant. However, owing to the presence of cotton (a natural, non-synthetic fibre), NyCo fabrics are no-melt/no-drip—at least they are above a certain threshold percentage of the cotton content.

Read more about no-melt/no-drip materials here.

What is 50-50 CORDURA NyCo?

If you encounter a product labeled 50-50 CORDURA NyCo, that means it’s a CORDURA-branded fabric containing NyCo (a material blend that’s exactly half cotton and half nylon). This product is no-melt/no-drip thanks to having so much cotton content, but it’s neither flame-resistant nor flame-retardant on it’s own.

What is 50-50 NyCo?

If you encounter a product labeled 50-50 NyCo, that means the materials making up the base of the fabric are an equal split between cotton and nylon.

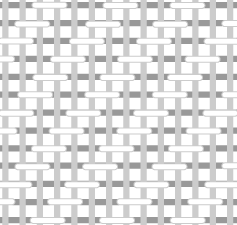

What is NyCo twill?

NyCo twill is a material made by using a weaving technique different from that which is traditionally employed to produce rip-stop fabrics. The main components of NyCo twill are nylon and cotton.

Image source: Wikipedia.com

Twill fabrics are recognizable by their distinctive diagonal-line pattern.

The benefits of using NyCo

NyCo is used extensively in the manufacture of tactical gear and apparel. The reason is it offers outstanding performance characteristics: abrasion resistance, durability, breathability, and comfort.

The NyCo we customarily utilize here at UF PRO is made most commonly by employing the weaving techniques of rip-stop and twill.

What nylon brings to the blend

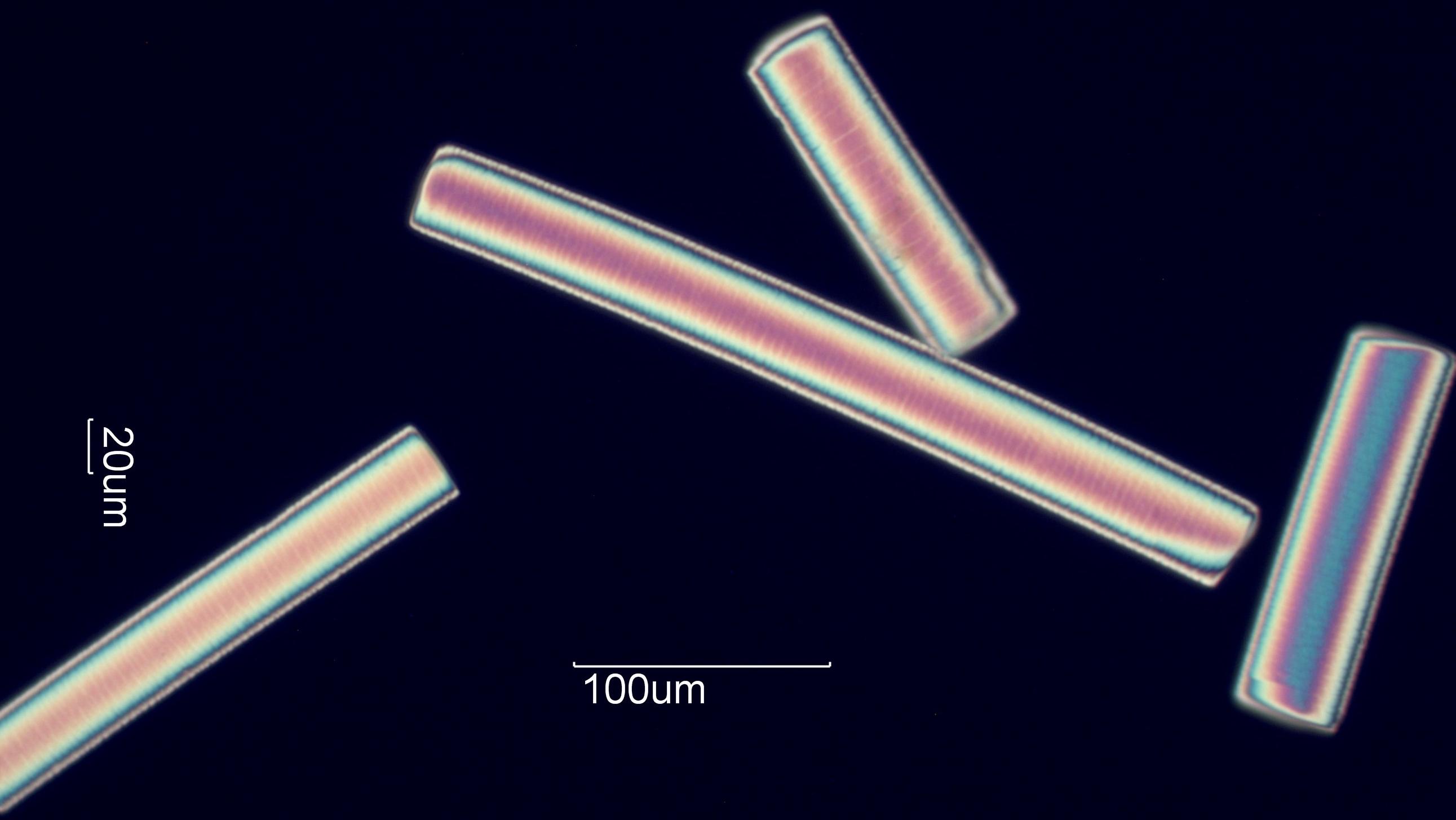

Nylon fibers under a microscope. Image source: microlabgallery.com

There are clearcut benefits of making nylon part of the NyCo blend:

- Great colour-retention

- High abrasion-resistance

- Durability

- High shear-strength

- No-melt/no-drip achievability

The disadvantages of using 100-percent nylon:

- Ounce-for-ounce, 100-percent nylon absorbs less moisture than 100-percent cotton

- Sticks to your skin when wet

There’s a myth about synthetic fibres that needs to be debunked—and right now is the time to do it. The myth: “You’re better off wearing 100-percent natural cotton in the tropics.” The truth: 100-percent synthetic clothing is better in the tropics because manmade fibres do not retain as much moisture as natural fibres do, so synthetics dry faster.

If you’re curious to know why synthetics dry faster, it’s because water stays on the fibre’s surface. In contrast, with cotton, the water infiltrates the fibre and stays inside it.

The advantage of 100-percent cotton is that, when the water seeps into the fibre, that fabric doesn’t stick to your skin. As a result, it feels better.

Even so, clothing made of synthetic fabrics is all-round better in the tropics because the high-moisture partial pressure there makes it more important that your clothes be able to quickly dry out.

Compare this to the “high heat, low water-pressure” scenario of a desert region. In an arid climate, more cotton is better because it absorbs more moisture that evaporates faster, thanks to the high temperatures and low-partial water pressure.

What cotton brings to the blend

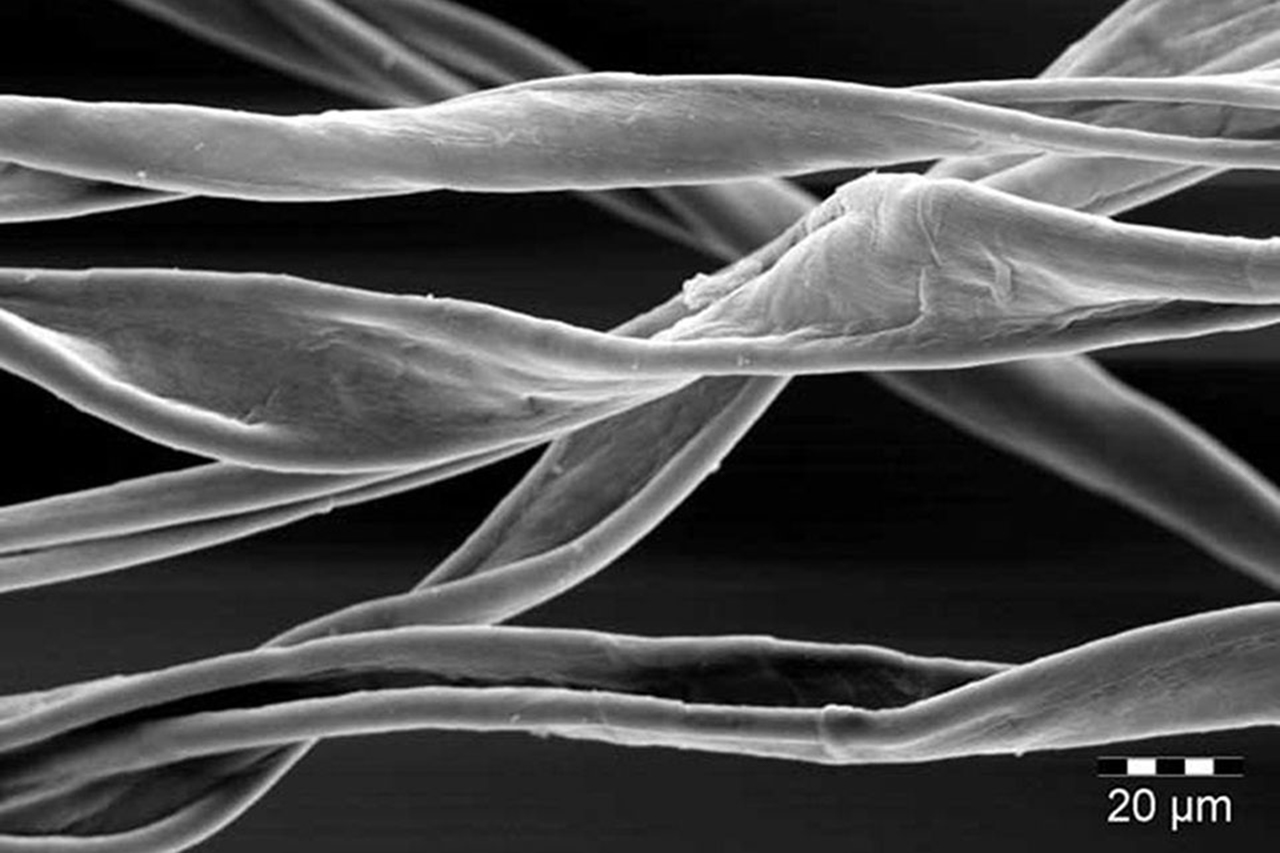

Cotton fibers under a microscope. Image source: asiantextilestudies.com

The benefits of using cotton:

- Comfort (the material is soft to the touch)

- Moisture absorbency

- Breathability

- No-melt/no-drip achievability if the cotton balance is within limits.

The disadvantages of 100-percent cotton

- Colour loss

- Abrasion-resistance diminishment (cotton is initially durable but readily degrades over time and becomes vulnerable to rippage; see jeans as an example)

- Moisture retention resulting in slow drying times (except in arid climates, where there is high heat and zero-percent relative humidity)

- “Lower weight movement” is non-achievable (hence the demand for products like NyCo Extreme 185g, which contains more nylon than cotton in order to reduce fabric weight and increase durability)

- Determining the limit of cotton’s no-melt/no-drip quality is difficult (but it is essential the limit be known)

NyCo alternatives

PolyCo fabrics

Polyester-cotton blends have similar properties to nylon-polyester, which is why PolyCo is NyCo’s main competitor.

The upside of using PolyCo in tactical gear and apparel is its softness, which makes it very comfortable to wear. It’s also cheaper to manufacture than NyCo. And it is only slightly less durable.

The downside of using PolyCo in tactical gear and apparel is (as noted above) it’s not quite as hardy as NyCo, which results in the need to repair or replace products sooner. A second disadvantage is no-melt/no-drip functionality is harder to achieve.

Despite the drawbacks to PolyCo, its advantages make this fabric a most viable alternative for tactical gear and clothing. Indeed, here at UF PRO, we use it in most of our unicolour garments.

Gear up with UF PRO gear in PolyCo fabrics here.

Polypropylene cotton (PP cotton) fabrics

Cotton can be blended with the synthetic thermoplastic polymer polypropylene to produce a material for the modern era—PP cotton.

The upside of using PP cotton in tactical gear and garments is it is lightweight. On top of that, PP cotton boasts excellent insulating properties along with the ability to manage moisture and dry very quickly.

The downside of using PP cotton in tactical gear and garments is its no-melt/no-drip properties are minimal (in its favor, though, the material does not easily catch fire). One other disadvantage: body odours cling to PP cotton and are difficult to eliminate.

Polypropylene is frequently used in base layer thermal insulation. The U.S. military previously employed PP in the garments comprising its Extended Cold Weather Clothing System, but has since switched to polyester.

Image source: Wikipedia.com

The future of this material

A day will surely come when NyCo loses its place at the top of the fabric hierarchy in the tactical space, replaced by new and better materials. That day is yet far off. But improvements being made now to NyCo are helping ensure it remains a favorite at least for the foreseeable future.

These are some of those improvements:

Change of blend ratio

Increasing the ratio of nylon in the blend decreases the ratio of less durable cotton and also lowers the overall product weight. However, no-melt/no-drip is the consideration that limits how much nylon the blend can have—the more nylon in the mix, the less no-melt/no-drip capability there will be.

CORDURA has been at the forefront of the push to change NyCo’s blend ratio. Consider, if you will, the brand’s NyCo Extreme, which features Invistia T420HT nylon technology. This material is high-performance because it contains 57-percent nylon made from this new Invisita base fibre (the finished material is lighter and stronger than other NyCo fabrics).

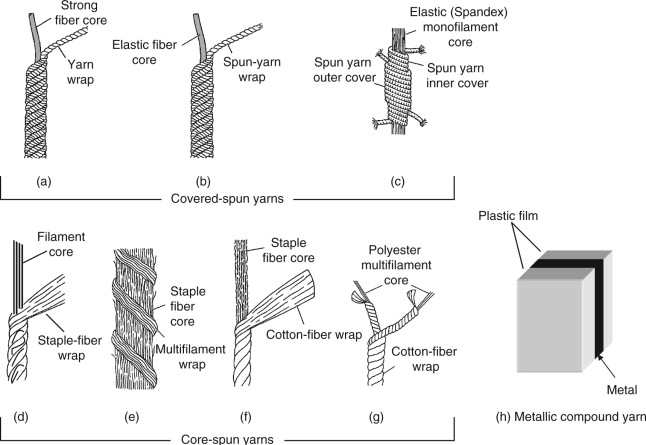

Change of yarn construction

An intimate-blend yarn is what they call it when various fibres are combined to form a single yarn. The purpose is to create a new type of yarn, but one that retains the properties of the base fibers.

CORDURA NyCo Tactical is a perfect example of an intimate-blend yarn. It’s made from nylon (specifically, Invistia T420 nylon 6,6 staple fibre) and cotton.

The way intimate-blend yarns are created has been largely unchanged for decades. But there is a different method now in development called the core-spinning technique.

Image source: Engineering Textiles (Second Edition), 2020

The benefits of core-spun construction are still somewhat theoretical. However, it is thought that the diameter of the yarns produced in this manner should be more evenly filled out than that of conventionally made intimate-blend yarns.

It is also expected that improved abrasion resistance, reduced hairiness, and better pilling resistance will be among the virtues of core-spun yarn.

If core-spun yarn lives up to these expectations, it could mean that tactical gear and clothing of the future will offer better performance than can be obtained from current intimate-blend production techniques.

Some of potential upsides:

Easier colouring (nylon is difficult to colour)

Better no-melt/no-drip properties (because cotton is wrapped around each nylon strand)

Browse UF PRO Tactical Gear Using NyCo

|