Poly cotton is a mainstream fabric extensively used in the tactical field. Its many outstanding propeties make it an ideal material for tactical garments. This UF PRO blog post traces the history of poly cotton, discusses the fabric’s benefits, and offers some predictions about its future.

In this blog post:

Introduction

Chances are that at some point in the past you’ve worn a garment made from a blend of polyester and cotton.

The reason is that this material’s characteristics are such that it’s less expensive to use in military and law-enforcement gear than the alternative—a blend of nylon and cotton.

In other words, poly cotton is a great economic solution.

But lower cost is not the only advantage of poly cotton. The material benefits tremendously from the combining of its two base fabrics. Polyester is a highly durable synthetic fibre. From it, poly cotton derives great strength. Cotton, on the other hand, is a soft, natural fibre. From it, poly cotton gains comfortableness.

A short history of poly cotton

Since poly cotton is a blended material, it will be useful to briefly examine the separate histories of each of the base fibres before recounting the past after they were combined.

The earliest recorded mentions of cotton date back roughly 7,000 years ago. It was available in most places around the world by the 16th Century.

Cotton use really took off with the dawning of the Industrial Revolution in the 1700s. In fact, the arrival of that era was ushered in by the invention of a machine to separate the seeds of the harvested cotton plant from the valuable fibres.

The machine was patented in 1793 and was called a cotton gin. We know. We’re as disappointed as you to have discovered that “cotton gin” is not an alcoholic beverage.

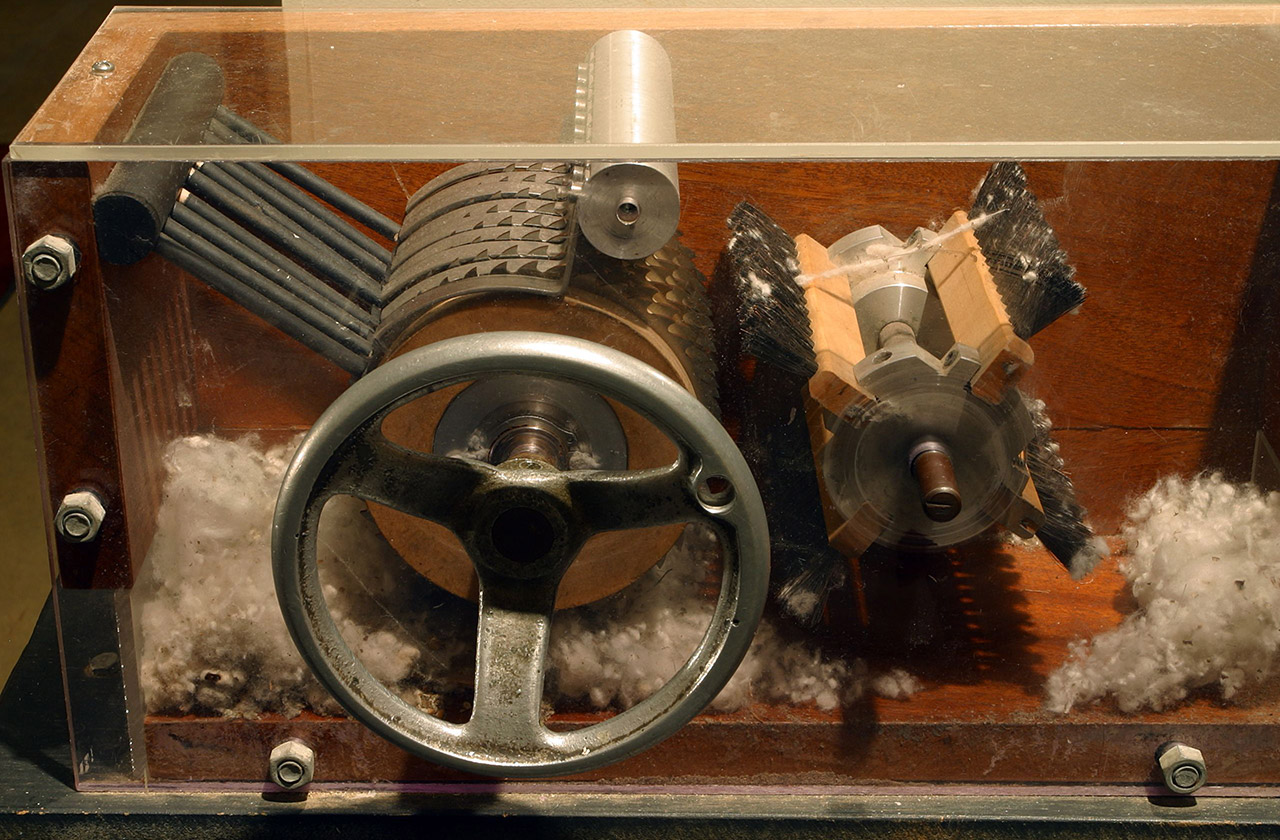

19th century cotton gin. Image source: Wikipedia.com

The rest is history (pun intended). Cotton went on to become the most recognised material in the clothing industry.

Then there was polyester. Its pedigree is much more recent than cotton’s. Polyester was discovered by British chemists John Rex Whinfield and James Tennant Dickson at a time when synthetic fibres were commercially on the rise. They tradenamed polyester Terylene but they also called it Dacron.

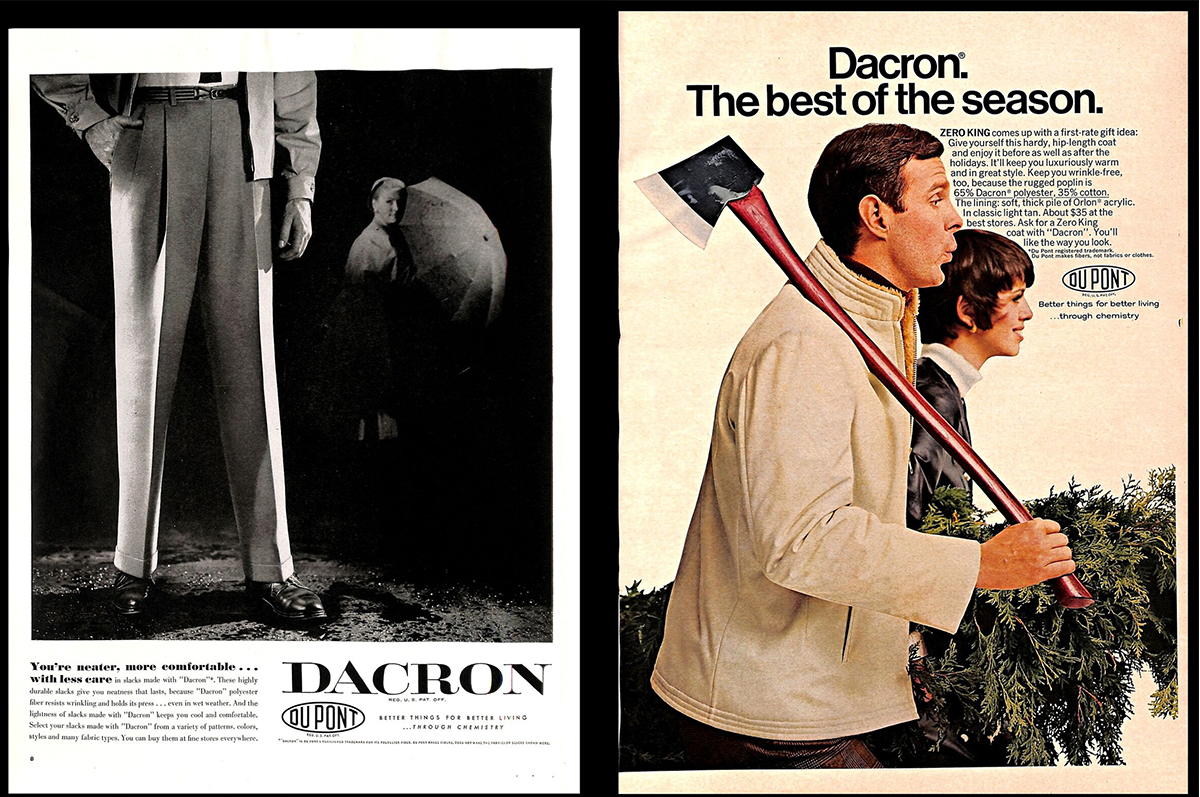

Two DuPont adds promoting the polyester fabric Dracon. Image source: americanvintageads

DuPont (the company behind the development of nylon) soon afterward came out with its own version of polyester. By 1946, DuPont had secured all legal rights to this material.

Then began the “polyester revolution”. It spread across multiple industries, including the fashion trade. However, polyester eventually came to be widely recognised as uncomfortable and lacking in aesthetic appeal.

Polyester makers and promoters feared the material would be relegated to the dustbin of history, so they hit on the idea of blending it with cotton in order to improve comfort and appearance.

The result was a material—poly cotton—that felt and looked better but that was still less expensive and vastly more durable than plain cotton.

FAQ's

What is poly cotton?

Poly cotton (polyester cotton or PolyCo) is a fabric made from two base materials. The materials are—as the name implies—polyester and cotton. Poly cotton is available as a blend (meaning, the fibre and yarns are made from this mixture) or as a discrete material constructed from yarns of cotton and yarns of polyester.

How do you wash poly cotton tactical gear?

UF PRO makes it easy to take proper care of your equipment. Simply follow the care tag instructions found on the inside of the garment. Read our guide on care tag instructions here.

How do you wash 60/40 poly cotton?

Poly cotton garments require no special care (as do, for example, waterproof garments) to retain their properties. Coloured (non-white) poly cotton materials normally can be washed in temperatures up to 60°C and can be tumble dried.

If your gear is made by UF PRO, you’ll find care instructions on a tag sewn to the inside of the garment. Simply follow the instructions to ensure proper maintenance of your gear.

How to waterproof poly cotton?

Waterproofness is not an inherent poly cotton property (in other words, the material doesn’t start out waterproof; it has to be made that way).

Poly cotton fabric can be made waterproof by laminating it with a waterproof membrane (GORE-TEX, for example). Alternatively, you can impregnate poly cotton with a water-repellent/waterproof coating, but doing so can severely impact the breathability of the garment.

Is a poly cotton blend easy to dye?

Yes. It’s much easier to dye than is NyCo and many other materials. The ease of dyeing is specifically one of the reasons European nations are so big on poly cotton.

Benefits of using poly cotton

Like any other blend, poly cotton was designed to compensate for the shortcomings of each base fibre. Remember, polyester is super-durable, but its flaw is uncomfortableness; meanwhile, cotton is super-comfortable but not very durable.

Let's take a look at the benefits of each base material:

Cotton benefits:

- Comfort (very soft)

- Moisture absorbency

- Breathability

- No-melt/no-drip properties

Image source: barnhardtcotton.net

Polyester benefits:

- High strength-to-weight ratio

- Quick drying

- Dyes easily

- Holds its shape

- Stain resistant

- No moisture absorbency

- Inexpensive alternative to nylon

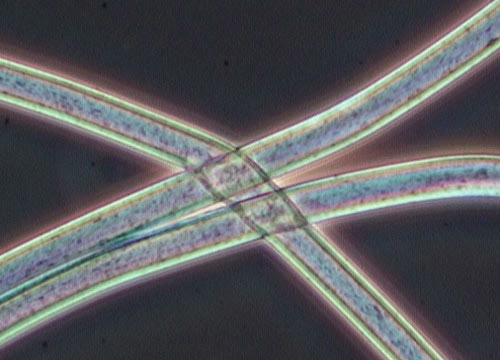

Image source: microscopyu.com

Now let’s look at the benefits of the blended material:

- Strong and durable

- Breathable

- Great color retention

- Economical (costs less than 100% cotton)

- Short drying time

The mixture which we mostly use in our unicolour tactical gear has a ratio of 67% polyester to 33% cotton. Field operators find the 67-30 blend a pleasure to wear and they appreciate the peace of mind that comes from knowing that it’s durable enough to withstand the brutal punishments they dish out every day.

NyCo vs poly cotton

Inevitably, comparisons are made between gear constructed with poly cotton and gear built with NyCo. While arguably NyCo has better “technical specs” than poly cotton (mainly with regard to strength and durability), poly cotton remains a viable choice.

At UF PRO, we always opt-in for the best. So why even consider poly cotton if NyCo is better?

Here are a few reasons why:

- Comfort. Operators demand garments they can wear 24/7 and experience no discomfort. Between NyCo and poly cotton, both deliver roughly the same amount of comfort.

- Availability. In Europe, manufacturers of NyCo fabrics are few and far between. The opposite is true for manufacturers of poly cotton. Also, even when you can find a European-based NyCo maker, there’s no guarantee the fabric will be available in specific camouflages (German camouflage Flecktarn, for example, comes only in twill poly cotton fabric).

- Price. Poly cotton costs less than NyCo (mainly because it’s so abundant in Europe). That makes poly cotton the more economic solution for European tactical gear makers.

Read more about NyCo in this article here.

The future of this material

It’s hard to imagine a future in which poly cotton loses ground to any other material and is surplanted. In our opinion, poly cotton fabrics are here to stay for the long run. But that doesn’t portend a dull future.

Various technologies are being marshaled to further improve the fabric. Nanotechnology appears particularly promising.

The first generation of nanotechnology aims to add to current fabrics a total of nine fields. They are:

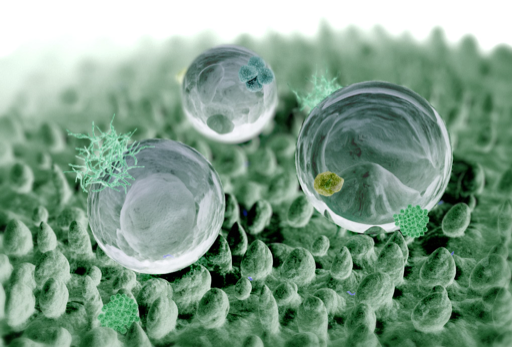

Water-repellency. Before the arrival of nanotechnology, it was a daunting challenge to add water-repellency without making the garment less breathable.

Image source: sustainable-nano.comAnti-static properties. Static electricty buildup in a garment can damage gear or equipment. It can also inadvertently activate devices. Anti-static garments would be invaluable in preventing those problems.

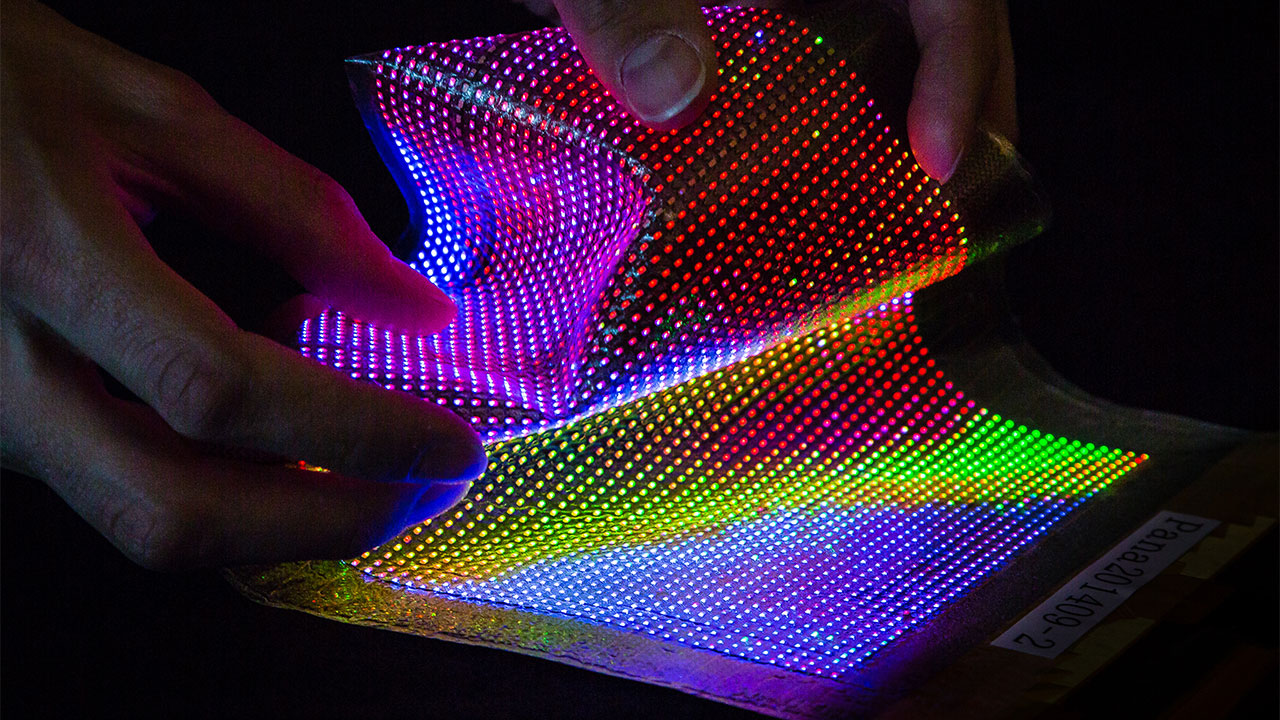

Optical displays. Nanotechnologies would permit building such displays right into the material. However, while an interesting potential addition, the current trend suggests this won’t be happening anytime soon—LE and military leaders aren’t keen to let operators wear battery powered gear that has yet to be proven and deemed reliable.

Image source: phys.orgSensors. Could be used on keeping tabs on the essential life functions like heartbeat, temperature, perspiration etc.

Antibacterial & odor control. Achieved by adding nanosilver.

Computing. This feature would allow operators to obtain vital information about their surroundings from the clothes they’re wearing. No more being at the mercy of coms and command centers for surroundings info.

Image source: technicaltextile.netFR properties, UV Blocking and self-cleaning. Adding FR to a standard article of clothing can be achieved with nanometal oxides. Meanwhile, adding zinc oxide in a polymer matrix can add a layer of UV protection.

Strength enhancement. Enhanced durability is possible by utilizing AlO3, CNT, SiO2, and various other materials.

Research and development into progressive technologies that promise to improve poly cotton is feasible because it doesn’t appreciably increase the material’s cost. Even with advancements added, cotton polyester remains more economical than NyCo.

Get more intel on the future of tactical clothing here.

Gear up with Polycotton UF PRO Gear