The significance of flame-resistant (FR) clothing cannot be overstated. It serves as a vital shield, protecting operatives from the dangers of fire and extreme heat. This blog delves deeper into the evolution, principles, and testing of FR clothing, highlighting the UF PRO Striker FR BDU and its performance in the Thermoman test conducted in Switzerland.

In this blog post:

- Difference in function of FR clothing based on profession

- The history of flame-resistant clothing

- The science behind flame-resistant and flame-retardant clothing

- Active and passive protection

- Comprehensive testing methods for flame-resistant clothing

- Advanced thermal mannequin testing

- UF PRO Striker FR BDU

- Conclusion

Difference in function of FR clothing based on profession

FR clothing for firefighters and tactical operators differs primarily in design and material focus. Firefighters' gear is designed for maximum protection against extreme heat and open flames, often heavier and more insulated. It prioritizes thermal protection and durability in prolonged fire exposure. In contrast, FR clothing for tactical operators balances flame resistance with mobility, comfort, and stealth. These garments are lighter, more flexible, and designed for quick, agile movements, suitable for a variety of operational environments where fire risk is a consideration but not the sole focus.

The history of flame-resistant clothing

Flame-resistant clothing's journey began in ancient times, with the discovery of naturally flame-retardant fibers like wool. However, the true revolution in FR clothing came with the advent of synthetics and advanced treatments in the 20th century. The development of materials like Nomex in the 1960s, a heat and flame-resistant fibre, marked a significant milestone. Such innovations were driven by the growing demand for effective protective clothing in industrial and military sectors, leading to the high-performance FR garments we see today.

SUBSCRIBE TO UNLOCK OUR EXCLUSIVE CONTENT

Enter your email and get timely updates and relevant intel on tactical topics directly to your inbox.

You are signing up to receive updates via e-mail from which you can opt out at any time. Visit our privacy policy for more info.

The science behind flame-resistant and flame-retardant clothing

The Fire Triangle is crucial in understanding fire safety. This model shows that fire needs three elements: oxygen, heat, and fuel. Removing any one of these elements prevents the fire from starting or continuing. For instance, most fire extinguishers work by eliminating the oxygen component, effectively suffocating the fire. This fundamental concept of fire behavior is key to understanding and implementing effective protection strategies against fire hazards.

Flame-resistant clothing, created from materials like modacrylic or aramid fibers, inherently resists ignition. The molecular structure of these fabrics is designed to char, creating a barrier and extinguishing the flame.

In contrast, flame-retardant clothing involves the application of chemical treatments to fabrics like cotton or polyester, enhancing their ability to resist ignition and slow down burning. This distinction is critical in selecting the right protective gear for different operational environments.

Active and passive protection

In high-risk environments, operators rely on two types of protection:

- Active Protection: This involves the operator's ability to react to a threat, such as moving out of harm's way or seeking cover.

- Passive Protection: This is where the physical and chemical properties of Personal Protective Equipment (PPE), like FR garments, come into play, providing essential protection against environmental hazards.

Both active and passive protection are critical for ensuring the safety of operators, enabling them to emerge from dangerous situations with minimal or no injuries.

In conclusion, while FR garments are indispensable in offering passive protection, understanding their limitations and balancing TPP and THL for optimal performance are key for tactical operators. This knowledge, combined with active protective measures, forms the cornerstone of comprehensive safety in hazardous environments.

Comprehensive testing methods for flame-resistant clothing

The vertical flame test explained

In the Vertical Flame Test, a fabric sample is exposed to a flame for a specified period and then observed. The key metrics include:

- After-Flame Time: The duration for which the fabric continues to burn after the flame source is removed.

- After-Glow Time: The time the fabric glows after the flame is extinguished.

- Char Length: The length of the damaged area, indicating the fabric's resistance to flame spread.

Heat transfer performance test

This test evaluates how much heat penetrates the garment under high-temperature exposure. It's essential for understanding the protective capabilities of FR clothing against prolonged heat and fire exposure.

Other Key Tests

- Arc Flash Testing: Measures the garment's ability to protect against electrical arc flash hazards.

- Flash Fire Testing: Simulates sudden, intense fire exposures to assess how well the garment protects the wearer.

Advanced thermal mannequin testing

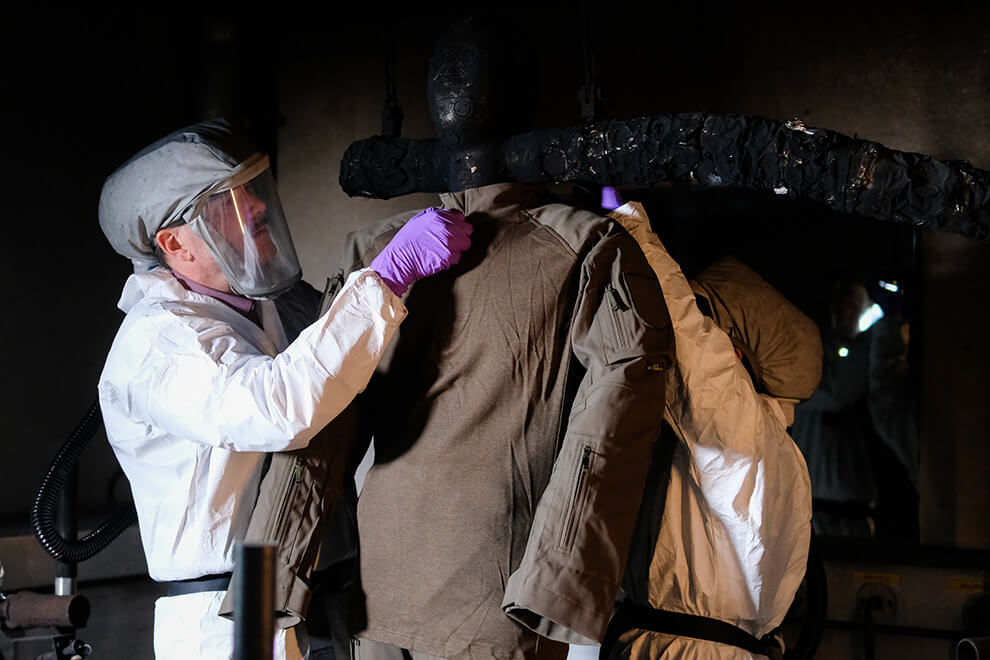

The Advanced Thermal Mannequin Test, or the so-called Thermoman Test, a sophisticated method, offers a realistic assessment of FR clothing. It simulates real-life fire exposure scenarios to evaluate the garment's overall protective performance. Sensors on the mannequin measure burn injuries, providing crucial data on the effectiveness of the FR clothing.

The Thermoman Test conducted at Empa involved subjecting the UF PRO Striker FR BDU to extreme fire conditions to evaluate its protective qualities. This test uses a life-sized, sophisticated mannequin equipped with numerous sensors that mimic human skin. The mannequin is dressed in the test garment and exposed to controlled flame and heat conditions, replicating scenarios that tactical operators might encounter in the field. This test, captured in a detailed video, offers compelling evidence of the Striker FR BDU's superior protective qualities.

The sensors on the mannequin provide a detailed analysis of the degree of protection offered by the clothing. They measure the potential burn injuries in various body areas, providing invaluable data on the effectiveness of FR clothing in protecting against severe burns. This test is crucial for assessing not just the flame resistance of the garment but also its overall performance in terms of heat insulation and material integrity under extreme conditions.

Why the Thermoman Test matters

The Thermoman Test is significant for several reasons:

- Realistic Assessment: It offers a realistic and comprehensive evaluation of how FR clothing performs in actual fire scenarios.

- Advanced Technology: The use of advanced sensor technology provides precise data on the protective capabilities of the garment.

- Safety Standards: Results from such tests are critical in setting and refining industry safety standards for flame-resistant clothing.

- Innovation and Improvement: Insights gained from these tests drive innovation, leading to the development of more advanced and effective FR clothing.

UF PRO Striker FR BDU

The UF PRO Striker FR BDU is specifically designed for tactical operators and excels in combining flame resistance with functional design. Distinct for its UF PRO cut and anatomical fit, it offers superior comfort even during extended duty hours. Its unique fit, dynamic stretchability, and smart material mix ensure unrestricted movement. Incorporating next-generation materials like the fire-resistant pyroshell™ technology, it exceeds expectations in both protection and comfort, proving lighter and more breathable compared to other FR materials, while meeting ISO fire protection standards.

Conclusion

The development and rigorous testing of flame-resistant clothing are pivotal in ensuring the safety of operators. From historical advancements to modern testing methodologies like the Thermoman test, the evolution of FR clothing reflects a continual commitment to protection and safety. The UF PRO Striker FR BDU exemplifies this evolution, offering an unmatched blend of protection, comfort, and functionality. For operatives, selecting the right FR clothing is a critical decision that impacts their safety and effectiveness in the field.