NIR, SWIR, FLIR. Those are acronyms for a few of the many different detection methods with which tactical operators must contend when they need to be concealed or simply to blend into their surrounding environment. NIR is one of the oldest of these detection methods. In this post, we explain what it means for an article of tactical clothing to be NIR-compliant, how it becomes -compliant, and what relationship this compliance bears to the camouflage pattern printed onto that garment.

In this blog post:

Introduction

Our bet is you’ve probably come across the topic of NIR compliance and faced some issues with it. On paper, this compliance is a must; ergo a lot of people ask us questions like, “Is MultiCam NIR?” Some of the questions make sense, but others don’t.

This is why it’s important to address this topic and debunk some common misconceptions about it. Let's start off easy.

Infrared vision has been around for million of years. Frogs, snakes, and fish are among the many animals that have IR vision. But not mammals. IR vision is absent from mammals (including humans) because mammalian eyes lack the proper receptors for it.

But humans can compensate for that shortcoming by improving our information processing. You see (no pun intended), the NIR spectrum offers us a lot of intel we would normally miss out on, especially as we are really dependent on light in the visible spectrum in order to be able to glimpse what’s going on around us at night.

This isn’t entirely bad because, even though it’s hard to see at night, the lack of visible light after sundown enables us to remain unseen while giving us the opportunity to tap into the NIR spectrum to observe and gather data.

And that’s why there are night-vision devices. The technology underlying them is mainly tied to warfare, as the ability to see in the dark was extremely useful for the military.

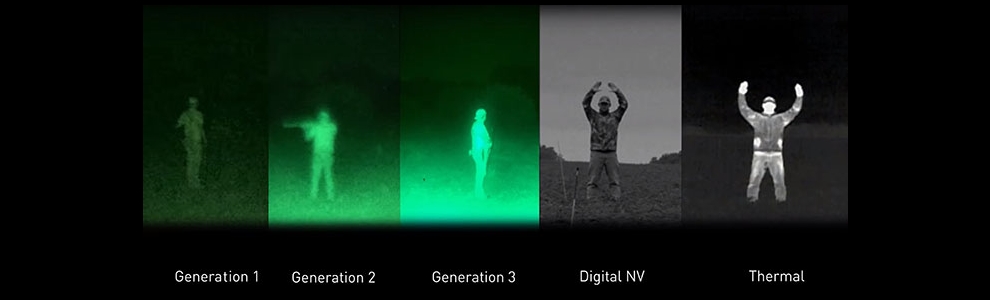

The first successful night-vision devices were developed in 1939 by Germany for use aboard Panther tanks. These initial devices are labeled Generation 0.

Image source Wikipedia.com

The next notable milestone in night-vision development was the war in Vietnam, which yielded Generation 1 technology. Both Generation 0 and Generation 1 night-vision devices worked by amplifying ambient visible light. Further research enabled the generations that followed to utilize not only ambient starlight and moonlight but also other spectrums including NIR.

NIR defined

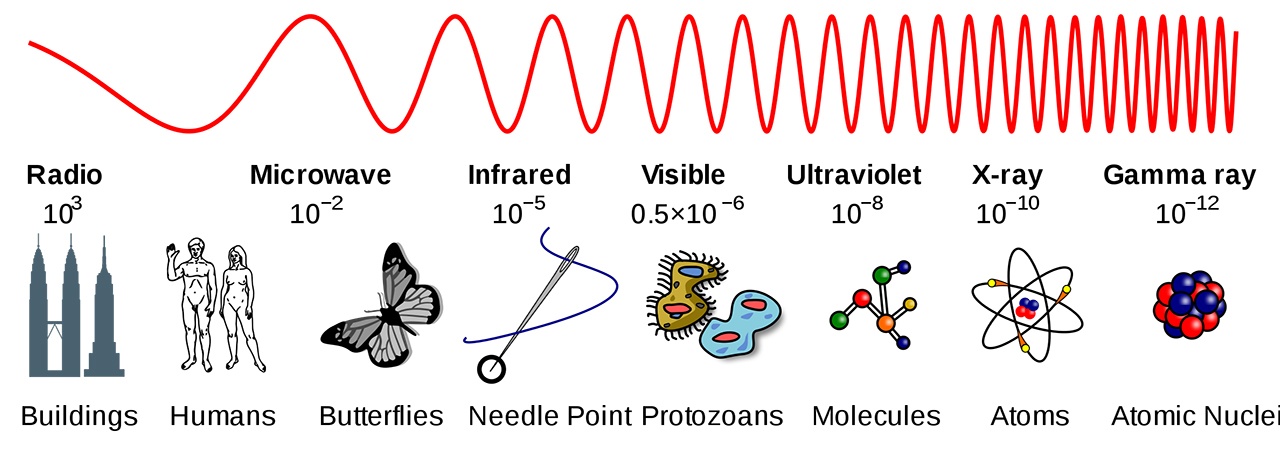

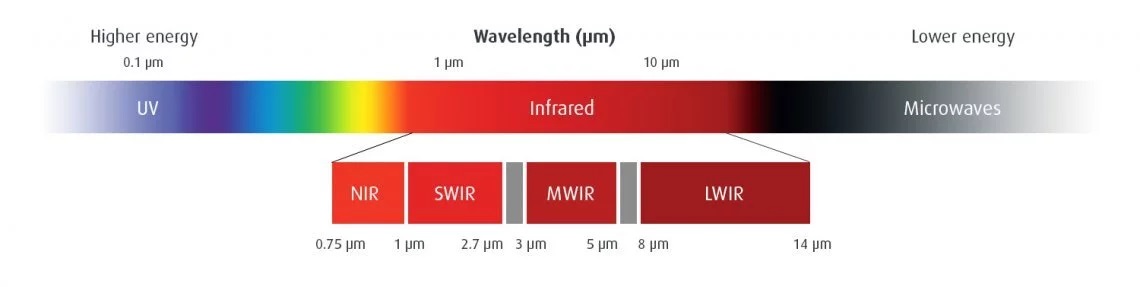

You probably know this one, but let’s mention it anyway. NIR stands for near-infrared and it’s used for denoting light that’s just outside of the visible range—basically that measured in the wavelength band between 780 nm and 2,500 nm.

Image source: Wikipedia.com

In addition to the benefits it offers the military, the NIR spectral range is also useful in science. Researchers use NIR to gather insights concerning the chemical structure of materials. Specifically, it’s possible to test the various chemical bonds of different materials by looking at their NIR-spectrum absorbency.

As mentioned earlier, NIR cannot be detected by the naked human eye and that makes it useful in the tactical space. Something else NIR does: when used in light-form imaging, it preserves more detail at longer ranges. Moreover, it’s not disrupted as easily by fog and haze as are shorter IR waves. Further, it results in images that are (for humans) clearer and more easily understood.

The downside of imaging in NIR is a “lack of colour.” NIR is outside our visible colour range and this prevents us from seeing what we perceive as red, green, or blue.

Another downside is the requirement that NIR light originates from a source in order to be bounced off objects.

How NIR affects clothing

If you’re concealed and the opposing team knows you’re out there somewhere, they’re going to be trying very hard to spot you. That basic fact of tactical life gives rise to the need for you to be equipped with detection-avoidance capability.

The best technology in support of detection-avoidance capability is the clothing you wear, since it covers most of your body. In addition to providing basic protection against the environment (rain, sun, wind, and so forth), your clothes also provide a platform upon which a camouflage pattern can be overlaid. In other words, you are already wearing clothes; in order for them to conceal you, they just need to be adapted.

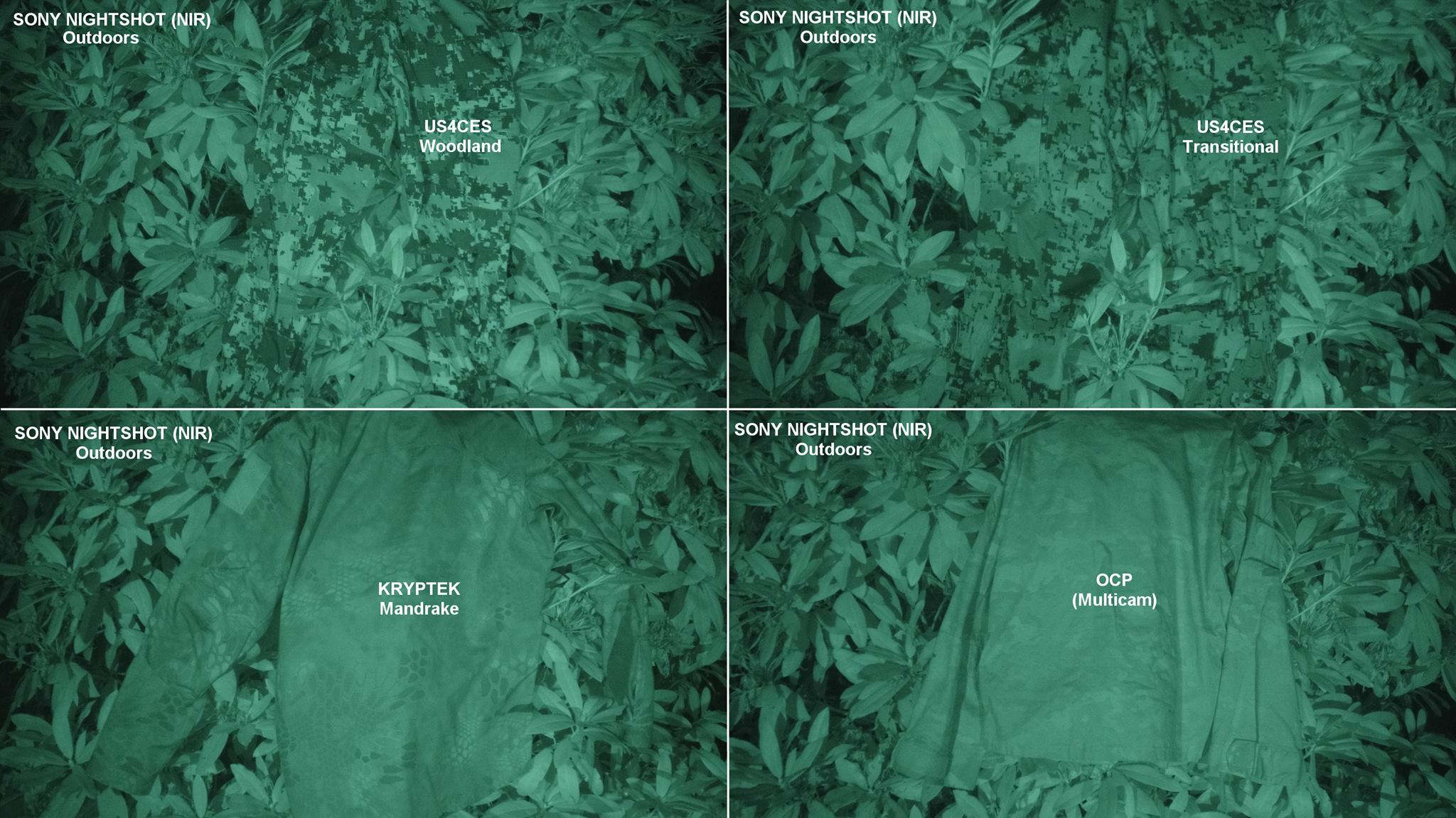

Image source: Hyperstealth.com

The goal of that adaptation is to configure it in such a way that it disrupts the outline of your body from the vantage point of someone looking in your general direction from a distance. That’s the goal, and it’s met with patterns like MultiCam and Flecktarn.

But, with NIR, there’s a twist. Think, if you will, of matching a uniform to a forest environment. In that environment are bark, leaves, and soil—all of them different in hue and shade. So the uniform’s camouflage pattern needs tans, browns, and greens. A hard job indeed. But what if the only colour present in the forest were green?

Imagine it. Green bark, green leaves, green soil. That would certainly make coming up with an effective camouflage pattern a lot easier.

Well, that’s actually the concept behind NIR masking. It focuses on one wavelength (in our example, the colour green) and tries to match the environment.

We choose green as the example because that’s what you see when you look through the eyepiece of a night-vision device. The images are green. Ever wonder why that is? It’s because green is the colour that human eyes tolerate best when having to look through a night-vision device for a lengthy period.

A good thing about NIR is that it does not translate “colour.” Instead, it presents light in varying degrees of intensity bouncing off objects such as trees, foliage, and soil. Matching this reflected NIR light with your environment is what we call NIR compliance.

A common misconception is that NIR compliance is something inherent to colours and camouflage patterns. The truth is that NIR compliance is a property of the fabric and of the dyes used on it.

Does this mean that within a single pattern—MultiCam, for instance—there can be multiple NIR properties? The answer is yes. It all depends on the type of dye or coating used.

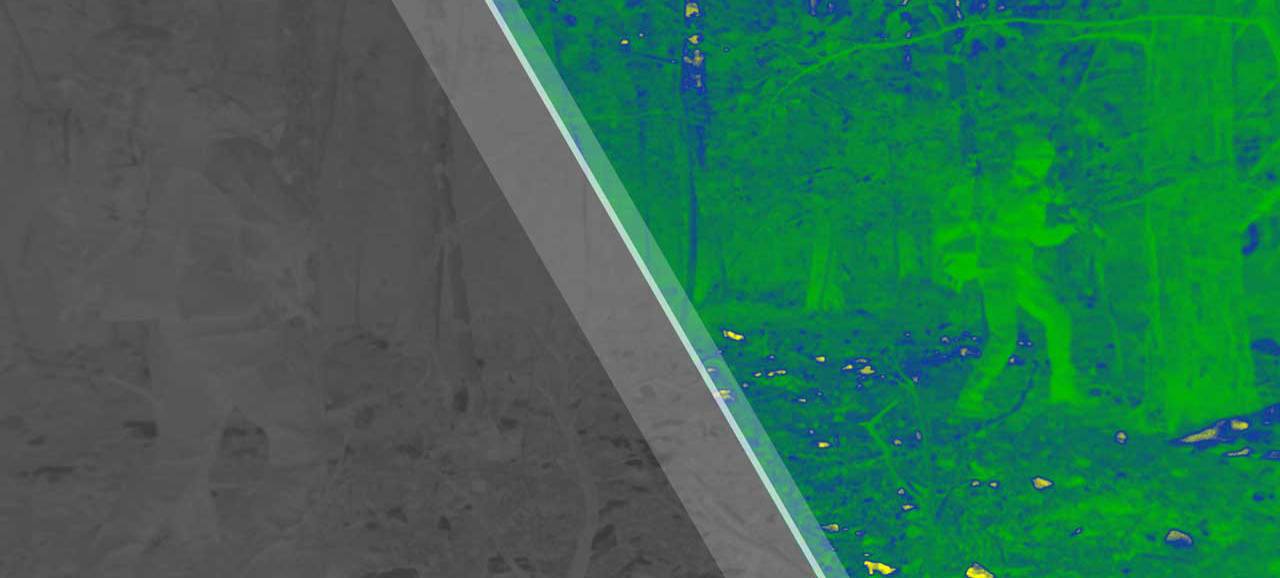

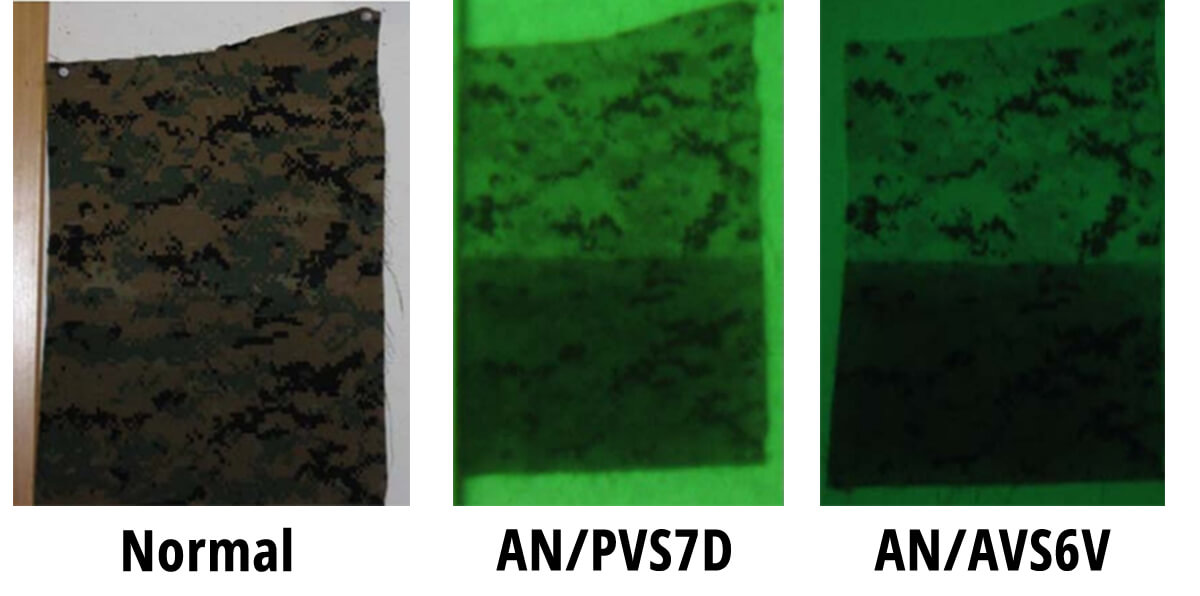

Image source: Hyperstealth.com

The image above illustrates best what we are trying to convey. Here, you see a regular MARPAT pattern fabric, but half of it is coated with a highly NIR-absorbent coating. The difference is clear. When you look at it through an NVG camera, you see that one half reflects light while the other half absorbs it.

In a sense, then, NIR-compliance is simply an additional layer of camouflage atop your garment’s existing pattern.

How clothing is made NIR-compliant

Now having cleared up the falsehood of dismal NIR performance being the fault of the camouflage patterns, we can move on to tackle another important issue.

As with other questions, you have to start at the beginning. In our case, the starting point is the fabric. PolyCotton and NyCo are very comfortable and durable fabrics—that’s why we use them. And because they perform so well, it would be unreasonable to seek substitutes in the quest for improved NIR performance. Instead, the smarter way to go is to look at improving the good fabrics we’ve already got.

It so happens that there are multiple ways of extending a fibre’s performance in the NIR spectrum. Namely, they are:

-

Physical modification

-

Surface modification

-

Modification by additives

In the last segment, you can find a large list of additives, but amongst them most notably dyes. As briefly mentioned above in the section “NIR defined,” NIR spectroscopy can be used to analyze chemical bonds; here, too, chemical composition comes into play. Chemical bonds play a major role in fabric absorption regions and can be modified to make the fabric more useful. By adapting them we gain what’s needed to achieve what we believe is the perfect camouflage.

“So let me get this straight,” you say. “Are you telling me that Ranger Green can be NIR compliant?” Yes, that’s exactly what we’re telling you. In fact, the U.S. army sparked a big push in CORDURA® 6,6 nylon filament by requesting an NIR-compliant desert-suitable uniform.

TrueLockTM EP technology was invented and provided the compliance needed for that uniform. TrueLockTM changes the fibre’s IR signature in the manufacturing stage, making that signature inherent to the fabric.

Image Source: cordura.com

TrueLockTM is not the only way to achieve low reflectance. But all other approaches are tied to materials and not to the patterns themselves. Remember, NIR compliance stems from the fabric itself, not the visual camouflage you see with your eyes.

So the short answer to the question of how to make NIR-compliant clothing is use the correct fabric.

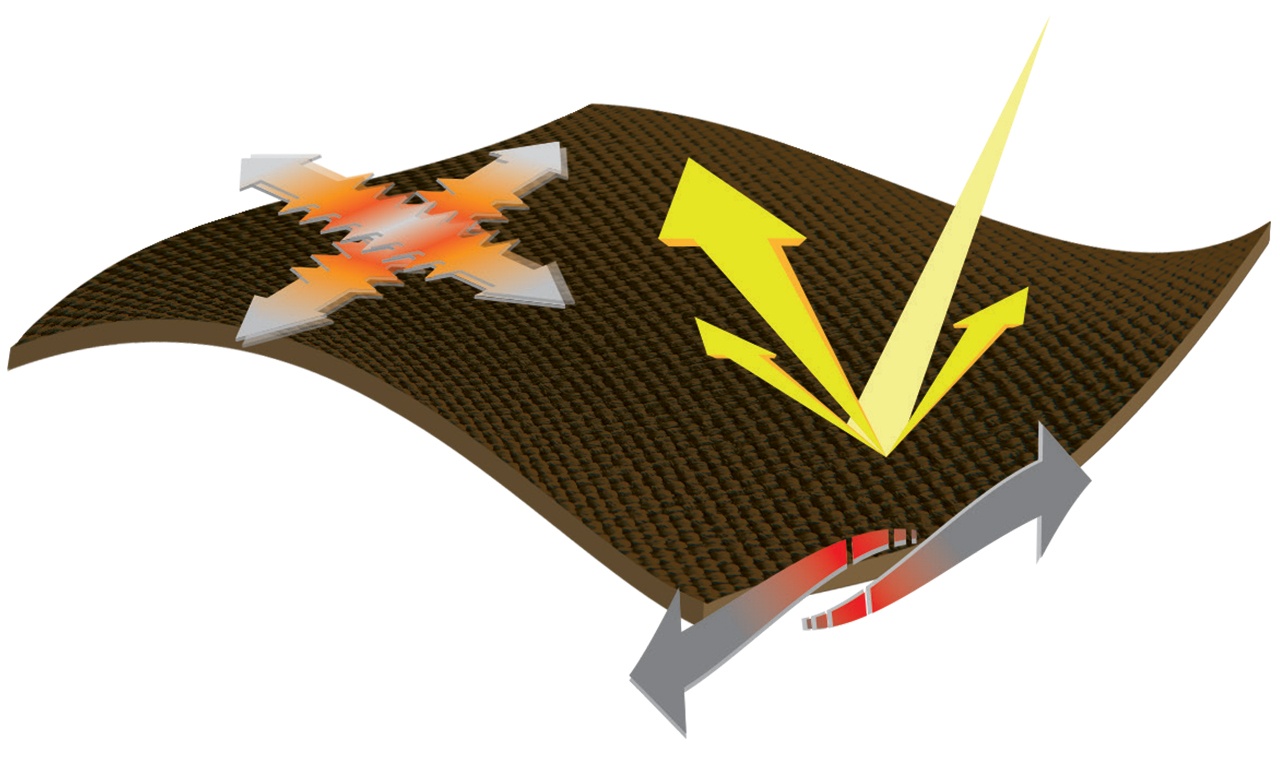

In contemporary tactical theatres, operators trying to maintain concealment face formidable challenges beyond traditional camouflage techniques, such as near-infrared (NIR) compliance. Emerging threats like Forward-Looking Infrared (FLIR) and other advanced detection technologies are posing new problems, leveraging a fundamental human characteristic—body heat. These technologies can detect the thermal signatures of operators, making traditional camouflage techniques less effective.

EXPLORING THE ROLE OF THERMAL SIGNATURE IN THE COMBAT ZONE

In this episode of Beer:30, Armin and Darko are joined by Marko Peljhan, co-founder and partner at C-Astral Aerospace, a globally recognised company that manufactures and services fixed-wing small Unmanned Aircraft Systems

THE QUEST FOR EFFECTIVE CAMOUFLAGE

As Armin, Darko, and Marko delve deeper into the challenges faced by tactical operators in the quest for effective camouflage, they bring to light the limitations of current technologies. They explore detection methods like NIR, short-wave infrared (SWIR), and FLIR, highlighting the importance of understanding these technologies to enhance operator concealment. The discussion emphasizes the urgency for ongoing research and development in the field of camouflage to stay ahead of these rapidly evolving detection methods.

A BATTLE ON THE THERMAL FRONT

The conversation shifts to the increasingly pressing issue of thermal detection. Armin, Darko, and Marko dissect the challenges posed by heat signature technology in the modern battlefield. They scrutinize the implications of soldiers' body heat and the importance of heat dissipation in tactical gear. The trio anticipates the potential of future technologies, such as advanced thermal fabrics and coatings, which could neutralize heat signature detection and boost operator concealment.

HEAT SIGNATURE MANAGEMENT

Heat signature management, a vital yet often overlooked aspect of modern warfare, plays a critical role in tactical operations. As thermal imaging technologies become increasingly sophisticated, understanding and managing heat signatures has become essential for maintaining effective camouflage in the field.

Heat signature management involves various strategies and technologies designed to reduce, disguise, or otherwise manage the heat emissions from personnel or equipment. This can include everything from specialized clothing materials designed to absorb or reflect heat, to heat-diffusing technologies that distribute heat in a way that makes it harder to detect.

However, managing heat signatures isn't just about the equipment. Understanding how heat is detected, including the limitations and capabilities of thermal imaging technologies, is crucial. This allows operators to use their environment strategically, such as hiding heat sources behind larger objects or using natural thermal cover like water bodies or thick vegetation.

In conclusion, heat signature management is a complex and multifaceted discipline that incorporates a blend of advanced materials science, tactical strategy, and a deep understanding of detection technologies. It represents a crucial front in the ongoing evolution of camouflage and concealment techniques in modern warfare.

SWIR TECHNOLOGY

Short-Wave Infrared (SWIR) technology is a powerful tool in modern warfare and surveillance, able to detect radiation in the short-wave infrared part of the electromagnetic spectrum, typically defined as light wavelengths between 0.9 and 1.7 micrometers. Unlike the human eye which can only perceive visible light (approximately 0.4 to 0.7 micrometers), SWIR sensors can detect a broader range of wavelengths, allowing them to "see" in conditions that would otherwise be challenging, such as through fog, haze, or dust.

SWIR technology is especially useful because it can detect reflected light, in contrast to thermal imaging that detects emitted heat. This means that SWIR can provide detailed images of objects even in low light conditions, as it is sensitive to reflected ambient light from the moon or stars. Furthermore, certain materials which are opaque in the visible spectrum, like silicon, are transparent in the SWIR range, providing additional capabilities for surveillance and detection.

A POWERFUL COMBINATION

When used in conjunction with thermal imaging, SWIR technology can provide a more comprehensive understanding of the environment. While thermal imaging is excellent at detecting heat differences and can identify humans, animals, or machines in complete darkness, it sometimes lacks the detail necessary to positively identify or recognize specific objects or individuals.

On the other hand, SWIR can provide those details, as it operates more similarly to traditional visible light cameras, albeit at different wavelengths. By using both in tandem, it's possible to not only detect the presence of heat-emitting objects but also identify what those objects are more accurately.

For example, a thermal camera might detect a warm object in a field but may not be able to determine what that object is due to the lack of fine detail in thermal images. However, a SWIR camera can capture those finer details due to its sensitivity to reflected light, allowing for positive identification. Therefore, the combination of thermal and SWIR imaging provides a powerful tool for surveillance, reconnaissance, and target identification in a wide range of conditions.

CONCLUSION

In the rapidly evolving landscape of tactical operations, NIR compliance continues to be a cornerstone of effective concealment. However, mastering the secrets of NIR compliance and understanding its role in camouflage is just the beginning. As the battlefield becomes more technologically advanced, operators must also grasp the principles of thermal signature management.