Polyester and cotton are widely known. But what sets them apart? Where do they have common ground? In this post, we dive into the details and touch on which is better for the tactical field.

In this blog post:

Introduction

This topic can be viewed as something larger than just one material vs another. Man-made fibres versus natural fibres are what could come into one’s mind.

In the tactical space, however, it’s uncommon to see garments in just one or the other. More commonly you’ll come across gear in PolyCotton, a mixture of the two. And with good reason.

The blend offers better performance for use in a professional environment, where comfort and durability are key. Nonetheless, both materials play an important role. Let's take a look at their properties and differences when used as a standalone material.

What’s under the hood?

Cotton and polyester are vastly different starting at their core. This manifests in the form of different properties between the two materials.

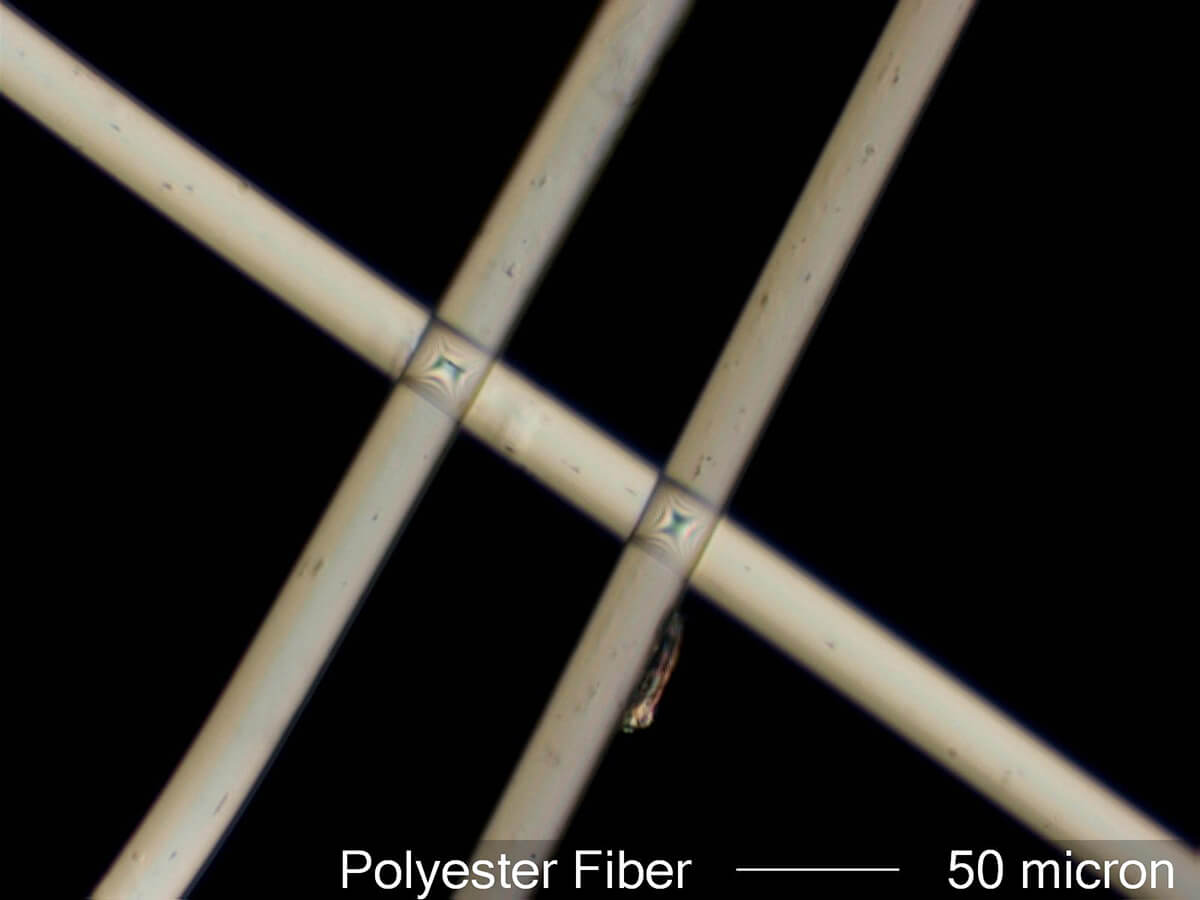

Polyester is a smooth man-made material also known by the name of PET. You probably heard of this acronym in the context of plastic bottles or another packaging. In a broad sense that's what polyester is, a type of simple plastic.

Image source: microlabgallery.com

A reason the garment industry avoids calling it plastic is the sidetone that comes with it. To name a few: cheap, not breathable and non-ecological, etc. It would potentially shine a bad light on a good product.

The fibres themselves are filled tube shape. Because of their chemical structure, they are hydrophobic (meaning they do not absorb water), strong & durable, and oleophilic (meaning they can absorb oils, thus they retain human odor).

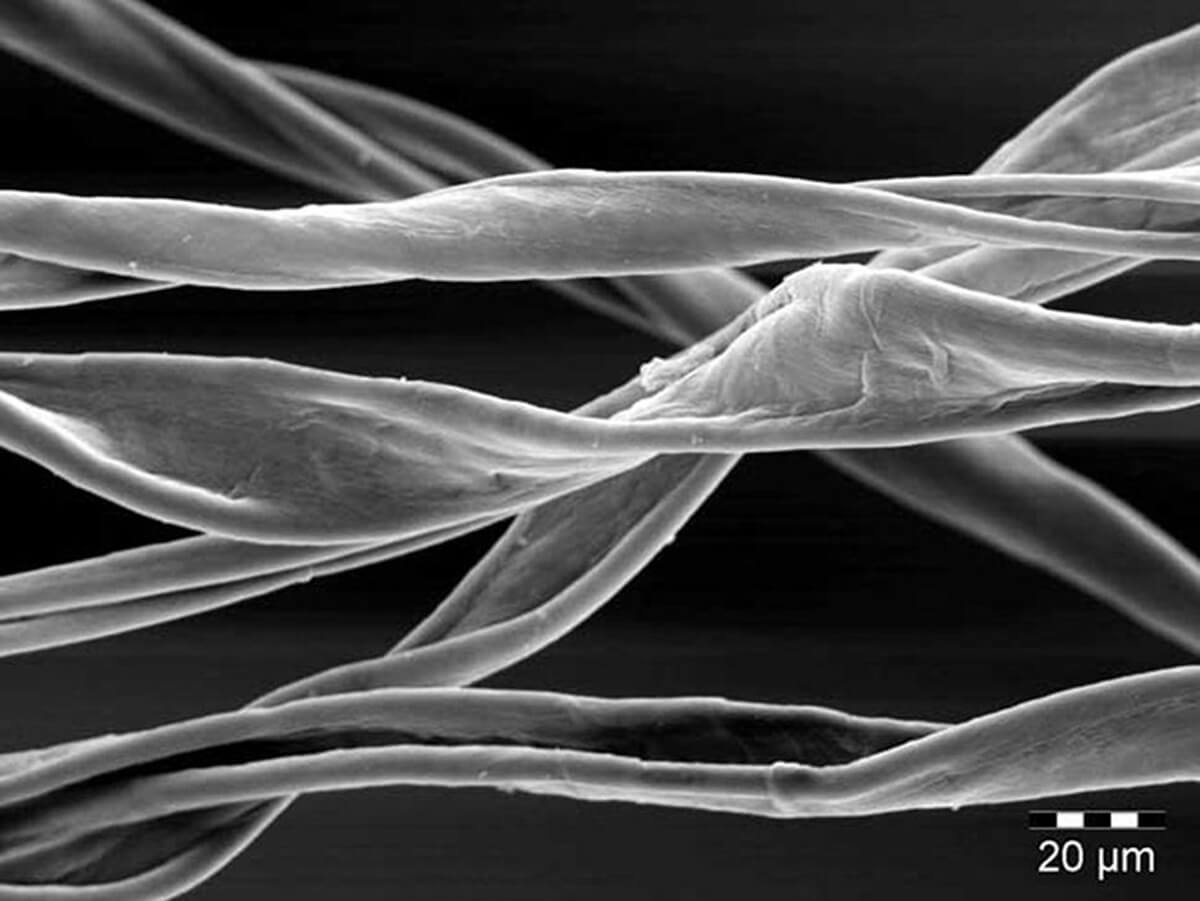

Cotton on the other hand is visually a completely different story. Instead of a smooth industrial look, it is more of what you’d expect to find in nature. A conglomerate of various dimensions, but with a common “twisted hollow ribbon” shape.

Image source: asiantextilestudies.com

Amongst the properties of the fibre there are hydrophilic properties (likes to absorb water) and resistance to static electricity buildup. The length and strength depend heavily on the cotton type (different plants with genetic modifications for example).

Difference in properties

From the different molecular structures come vastly different properties of the two materials. We’ve already talked about PolyCotton in this blog post and the same categories apply here.

The upsides

|

Benefits of Cotton |

Benefits of Polyester |

|

Comfort (the material is soft to the touch) |

High strength-to-weight ratio |

|

Moisture absorbency |

Quick drying |

|

Breathability |

Dyes easily |

|

No-melt/no-drip when enough percentage used |

Holds its shape |

|

|

Stain resistant |

|

|

Inexpensive alternative to nylon |

The downsides

|

Benefits of Cotton |

Benefits of Polyester |

|

Abrasion-resistance diminishment |

No moisture absorbency |

|

Moisture retention |

Melting when exposed to heat |

|

Durability |

Static electricity buildup |

|

Mediocre strength-to-weight |

Absorbs oil and grease |

|

|

Not comfortable |

Synthetics vs natural fibres

A topic that’s worth mentioning at this point is the clash between “natural” and man-made fibres. We put the word natural in quotes because modern-day cotton can be highly processed and has a massive environmental impact (large water consumption, insecticides, etc.)

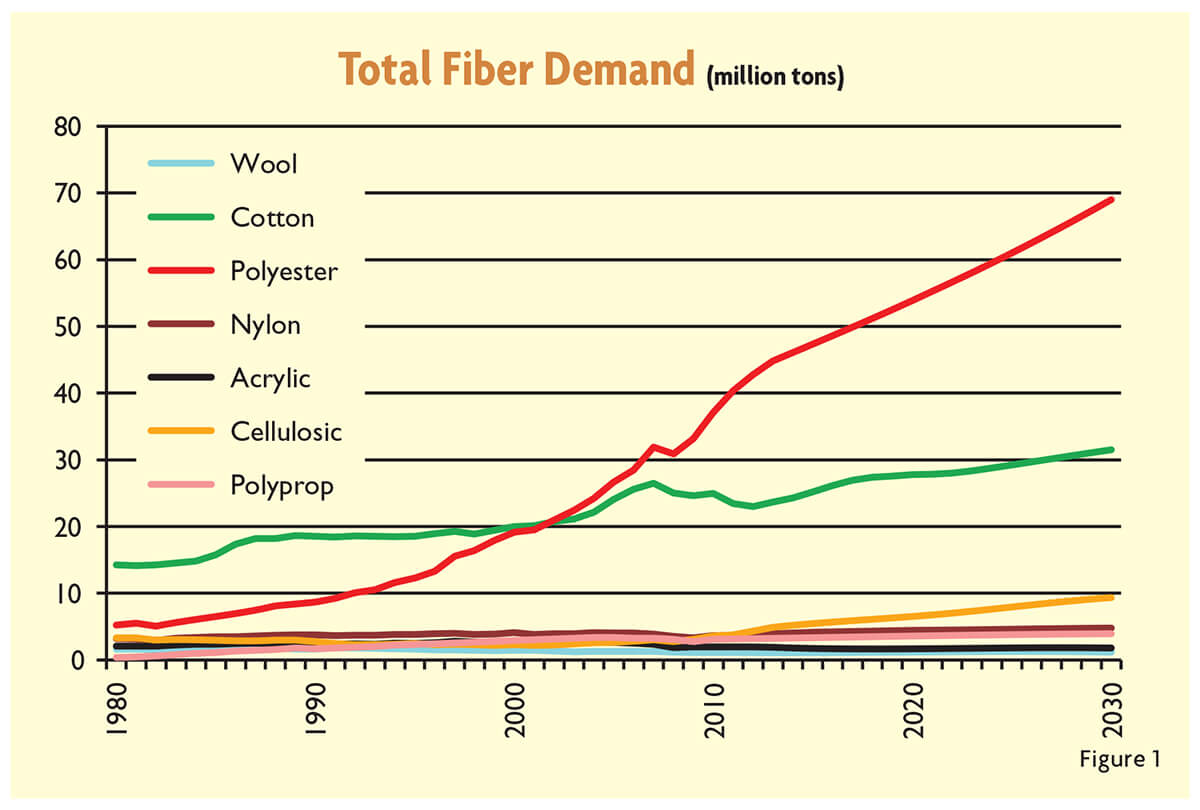

Our global demand for polyester has surpassed cotton in 2002 and has not stopped increasing since. Understandable as its manufacturing process is highly automated and produces expectable results. Cotton on the other hand has to be grown, depends on variable circumstances like temperature, rain, and other environmental aspects.

Image source: textileworld.com

While it’s most definitely not a consensus that man-made is bad and natural materials are good. There is some stigma surrounding it. This doubt comes from the lack of better understanding of why materials are what they are.

Synthetic materials are a gap filler. They fit in where natural materials lack features, be it waterproof properties, thermal insulation, high strength. They can also be a more viable economic solution for manufacturers and if used correctly offer exceptional value to the customer.

Food for thought: if you are certain natural materials are “eco-friendly” and just plain better for the earth there’s a hard reality check. Cotton farms are one of the largest insecticide consumers in the world with a 16% share.

Which is better for tactical use?

Short answer is none. Each of these has its downfalls if we were to use them as a standalone material. A true statement would be both when used together in a blend.

We do have some historical insight to support this claim. Rewind to the mid 20th century when soldiers used 100% cotton twill combat uniforms. The upside to using thick cotton clothes is that durability doesn’t take a hit.

Unfortunately, they were extremely slow to dry because of the sheer thickness and cotton’s ability to absorb moisture (by 25x their weight), which also added a lot of additional weight. Which you can imagine both cause significant problems for someone wearing it 24/7.

With this set of issues with the current uniform, the next logical step was to try the other extreme, a full polyester set. This of course turned out to be an even worse idea. Uniforms would develop a heavy smell, there were issues with breathability, sweat management, and that uncomfortable feeling of a fabric sticking to your skin.

As both approaches failed, middle-ground came to the rescue, and uniforms made from 50-50 PolyCotton were selected and remain in use to this day in both military and law enforcement circles. Think of Flecktarn as the default example.

Another aspect is once you start to consider the temperature of your environment. For cold environments, polyester is plain better. Think of fleece (primarily made from polyester) where the fibres are fluffed up to trap your body’s warm air and keep you insulated better. Also, the inherent non-retention of moisture makes it a suitable outer layer in rain, snow, and other conditions.

Turn the temperature up a notch and pure cotton becomes a better option with better moisture management and breathability.

It all depends on which way you turn the ball.

Outro

Two materials with vastly different properties somehow still manage to compete in the same category, clothing. What’s even odder is that when used together in polycotton they produce outstanding results.

In a world where our actions wouldn’t have consequences and we could wear a uniform for a day then toss it, it would be viable to opt-in for just a thin cotton uniform. Great wear comfort no need to keep it intact for weeks and months. But the reality is where longevity and durability are kings. Polycotton is here to stay for the foreseeable future.

Get UF PRO Gear in Polycotton