Different variations of the Primaloft insulation all share common characteristics. They are lightweight, easily packable & great thermal insulators. In this blog post we share an insight to this thermal insulation material and put it in a head to head battle with our current in-use G-Loft material.

In this blog post:

Introduction

Thermal insulation materials like Primaloft, Polartec & G-Loft are the key components in low-temperature tactical gear. They must have specific properties that make them suitable for tactical use, like low weight, excellent moisture management, and protection against the elements.

Primaloft looks to mimic down feathers, similar to other synthetic fibers while avoiding the downfalls like water absorption, long reinitialization time after being compressed, and the high price of manufacturing.

The history of Primaloft

It all started in 1983 and the Natick U.S. Army Research laboratory when they reached out to PrimaLoft’s parent company Albany International Corp. They were asked to develop a water-resistant synthetic alternative to goose down for use in military sleeping bags and clothing systems for cold-weather environments.

The U.S. Army was primarily interested in a synthetic insulator with comparable properties to down. The key categories discussed were weight, compressibility, thermal insulation, and performance when wet.

Image source: Wikipedia

Two versions were developed in this effort. One of the versions was a blend of non-woven Polyester fibers with similar dimensions to those found in down. This version went on as the PrimaLoft ONE.

In 1985, a US Patent codename "Synthetic down" was filed and ultimately approved a year later. After acquiring the patent, PrimaLoft was established as a subsidiary of its parent company. The military ultimately did not choose PrimaLoft as their choice for this effort, namely because of cost and durability loss in the rough military laundering process.

After the initial rejection from the U.S. Army the company went public on the market with the first commercially available garment by an outdoor recreation company called L.L Bean, since then it has become a staple in the thermal insulation materials industry.

The company is also involved with leading the industry in recycled content and sustainability aspects of manufacturing, with their Primaloft P.U.R.E. (manufacturing process) and PrimaLoft BIO (first biodegradable insulation and fabric).

If you noticed how frequently the word Loft is used when talking about thermal insulation (PrimaLoft, CoreLoft, G-Loft), it is not a coincidence. PrimaLoft began the trend of using it and becoming a synonym for warmth.

Loft represents the thickness of a product filled with compressible insulating material. Inferring that thicker layers are better insulators.

Quick Facts about PrimaLoft

What is Primaloft?

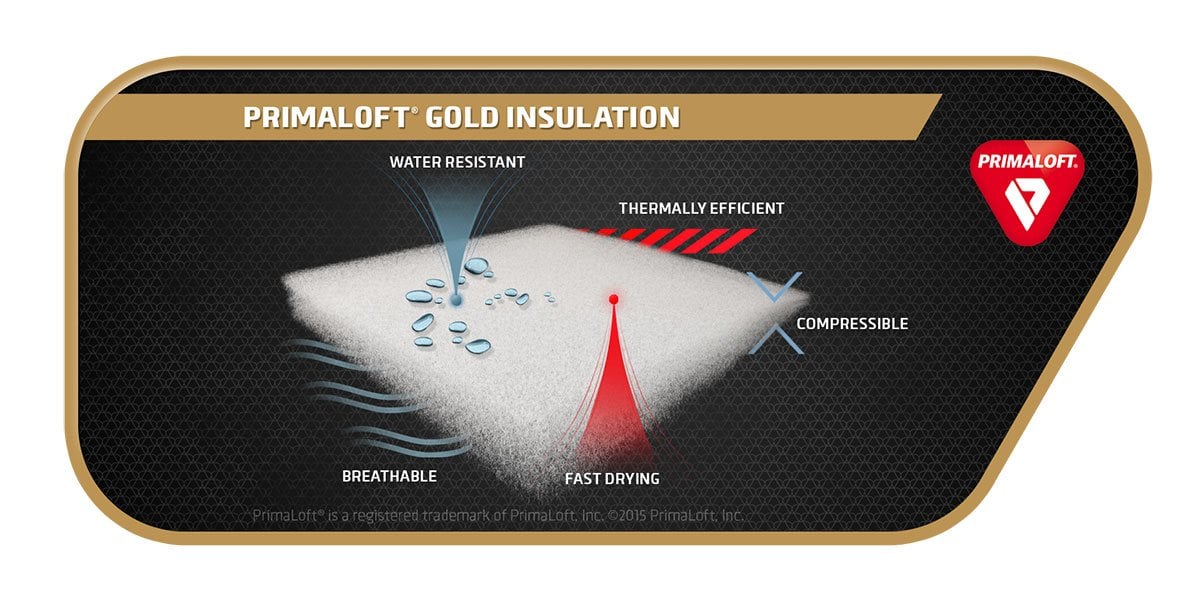

PrimaLoft is a synthetic non-woven thermal insulation material that was designed as a replacement for down, mainly to resolve the downs inability to function while wet.

How warm is PrimaLoft?

Primaloft Gold insulation is rated with a CLO value of 0.92, which roughly translates to 500-550 fill power down.

CLO is the mass of material per m2 that allows you to maintain your body temperature at 21°C (70°F) when resting.

How long does PrimaLoft last?

Taking proper care and storing the garments by not compressing them ensures long lasting thermal performance of more than 10 years.

Is PrimaLoft down?

No. Altho it’s often referred to as “manmade down”, this thermal-insulation material is derived from a patented synthetic microfibre.

The material structure

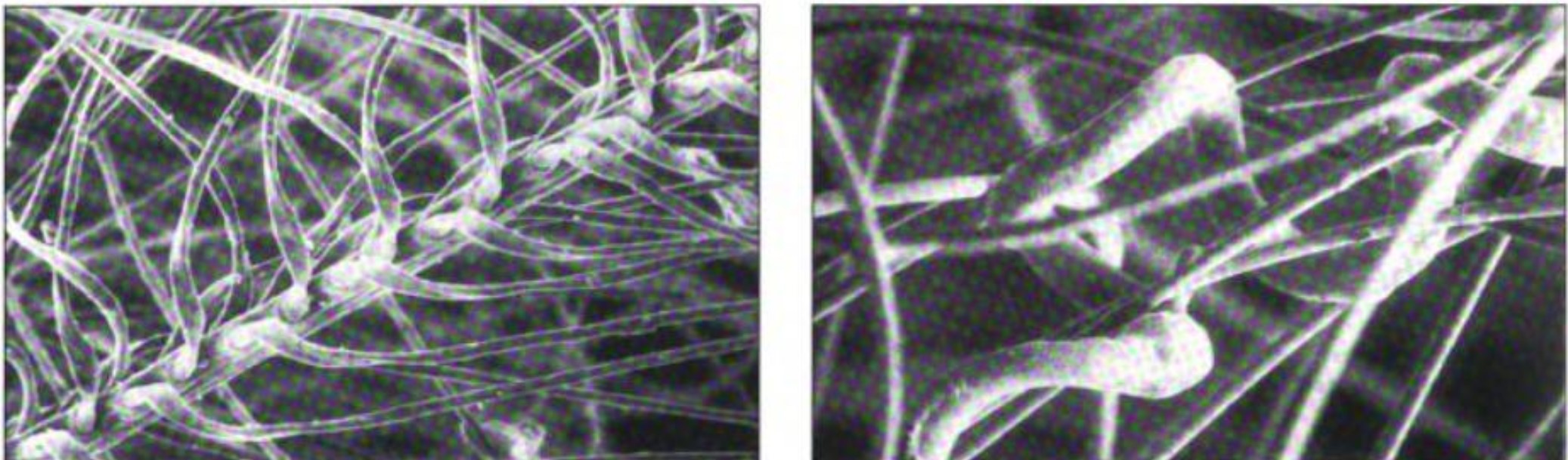

The structure itself stems from the original patent filed under US4588635A known as “Synthetic Down”. In the doc, the material is described as a blend of synthetic, spun and drawn, crimped, staple polyester microfibers with a diameter from 3 to 12 microns.

Image source: Primaloft.com

When you think about why this is such a good replacement for down filling it starts to make sense. Extremely small fibres mushed together create uncountable air pockets and trap body heat to keep you warm, the principle used with any other thermal insulation gear.

Scanning electron microscope images of down (left) and PrimaLoft (right).

Image source: Army RD & A

At its core, it works like down filling. The added benefit of using polyester as the base fiber is that it does not absorb water. This material can keep 96% of the insulating ability when wet, by maintaining thickness or loft.

PrimaLoft vs G-Loft

Nature often gives ingenious solutions to everyday problems. PrimaLoft originates from mimicking the properties of down.

G-Loft took the next obvious frontrunner - polar bear fur, an animal capable of withstanding the harshest winter conditions. The base of this material is a bi-component spiral fiber. Just like the polar bear’s fur, it’s hollow. Visually it resembles a spring.

Image source: G-Loft

Thanks to this unique spring structure, the material easily jumps back into its existing shape when you compress it e.g. store a jacket in your backpack.

The fibers then form natural clusters similar to those found in down insulation and create air pockets, which retain body heat.

Image source: G-Loft

Let’s compare the main features of both materials, that are directly considered when talking about thermal insulation tactical gear:r

|

Property |

PrimaLoft |

G-Loft |

|

Base fibre |

Micro Polyester |

Bi-Component spiral |

|

Per. effective when wet |

95% |

80% |

|

Fill-Power |

500-550 (good) |

700 (excellent) |

|

Compressible |

Yes |

Yes (with memory effect) |

This head-to-head comparison brings us directly to our next segment.

Why do we use G-Loft in our tactical gear?

Looks like PrimaLoft is just stellar as thermal insulation gear. But when talking about specifically cold-weather tactical gear it all boils down to 5 points.

1. Thermal insulation

This point is fairly straightforward as it can be measured. Let's briefly mention what fill power is.

Fill power is a measure of a material's ability to trap air (in term retains your body heat). Higher numbers mean better insulation.

In the case of tactical gear that means less bulk for the same effect of keeping you warm, which is something you want in any tactical garment.

Winner: G-Loft

2. Compressibility

Another point crucial for tactical gear is packing the mission-critical gear in your backpack.

Here the advantage goes again to G-Loft and the spring mechanism or “memory-effect” which is better at returning to the previous state.

Winner: G-Loft

3. Breathability

Both materials offer great breathability and water vapor management, so we’ll call this a draw. Another note is that breathability is affected by other layers in the garment, the face fabric and inner layer are most notable here.

Winner: Draw

4. Durability and care

The durability and care was the reason the US Military dropped PrimaLoft as the frontrunner in the race for military sleeping bags and clothing systems.

There are also reports from users after long time use that Primaloft loses some loft properties through the years.

G-Loft on the other hand does not have such downfalls thanks to the natural clustering of its base fiber.

Winner: G-Loft

5. Susceptibility to water

Both Polyester of PrimaLoft and the bi-component base fibre of G-Loft do not retain moisture. The Loft or insulation properties are minimally affected when wet and retain thermal insulation properties.

Comparing the 95% retention of thermal insulation properties from wet Primaloft to 80% of G-Loft’s the former is the winner on paper, but not when looking into the calculations of the base fill powers:

- Primaloft: 95%*550 = 522.5

- G-Loft: 80%*700 = 560

Because of the higher base fill power, G-Loft comes out on top, by a slight margin.

Winner: G-Loft

Conclusion

PrimaLoft started out as a top contender in the U.S. Army efforts to design a totally new cold weather system focusing on durable and weather versatile sleeping bags and clothing systems.

It went on to become one of the most recognised names in cold-weather clothing and a synonym for quality alternative to down insulation.

Despite the benefits and great sub-zero performance it’s still not quite as good of a solution for our application as is for example G-Loft, Polartec and others. The high-end tactical garments require a specific set of characteristics to be viable as a solid choice. In our case that is G-Loft.

Vous en voulez toujours plus ?