What is FR clothing? What are its limitations? What should you know before you opt to using it? In what ways is it different from clothing made of No-Melt/No-Drip materials? What advantages does it have for operators? In this blog post we tackle the most-asked questions about flame-retardant clothing and offer special insights concerning what makes this type of garment necessary for tactical operatives.

What's in this blog post?

What is FR clothing?

Clothing that bears the designation FR (for example FR shirts and work pants) is capable of providing some degree of protection against flames.

There are two distinct types of FR clothing. They are flame resistant and flame retardant.

- Flame-resistant clothing is that made from fibres that don’t easily ignite when exposed to fire (more on this in the pyroshell™ section of this blog post). The flame-resistance quality of the clothing can never be washed away or reduced from wear over time. Nomex fabric is a well-known example of this.

- Flame-retardant clothing is made from materials that self-extinguish in the event they ignite. Clothing in this category are also known as FRT, which stands for flame-retardant treated.

Actually, both flame resistant and flame retardant clothing are self-extinguishing—and that’s a characteristic you should look for when shopping for adequate flame protection.

Actually, both flame resistant and flame retardant clothing are self-extinguishing—and that’s a characteristic you should look for when shopping for adequate flame protection.

Also, both types reduce your risk of sustaining burns or, in the event your skin does come into contact with fire, they will help keep the burns from becoming severe.

Still, there are two significant differences between the two. First is duration of functionality. Second is ability to hold up to the punishment of repeated washings.

Inherently flame-resistant fabrics retain their functionality, whilst FRT materials tend to lose some of their functionality from lengthy use. Consequently, the latter is less expensive and more accessible to different organisations.

SIGN UP FOR MORE INTEL LIKE THIS.

Enter your email and stay in the know with future topics on FR garments.

Vous vous inscrivez pour recevoir des mises à jour par e-mail, dont vous pouvez vous désabonner à tout moment. Lisez notre politique de confidentialité.

How does FR work?

The goal of FR fabrics is to protect you from flames and potentially also heat, shielding you from receiving serious burns.

To better understand how to protect yourself from hazardous fires, you must first understand how fire works. For that, you must also identify its key parts.

“If you know yourself but not the enemy, for every victory gained you will also suffer a defeat.”

-Sun Tzu, The Art of War

The Fire Triangle

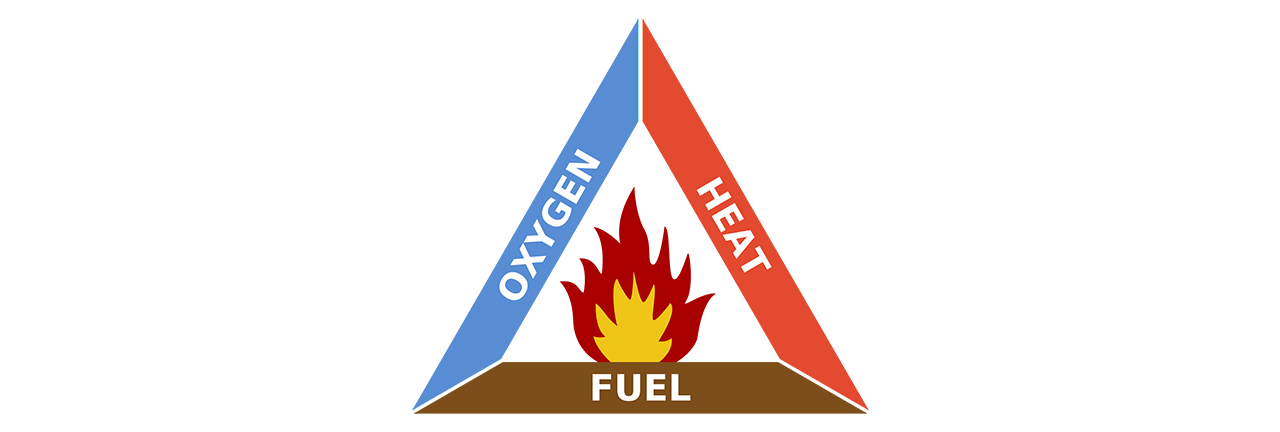

A simple model for understanding what most fires need in order to occur is known as the Fire Triangle (also referred to as the Combustion Triangle).

Image source: wikipedia.org.

The three key ingredients of a fire are:

- Oxygen

- Heat

- Fuel

Remove any one of the legs of this triangle and there will be no fire (or, if there is a fire, it won’t be able to sustain itself).

Most fire-extinguishing devices work by removing the “oxygen” part of the combustion triangle. This results in the fire “suffocating” for lack of air and thus oxygen.

With this overview of how our enemy operates now in hand, we can delve deeper into the explanation of how to protect yourself from it.

Fire-resistant fabrics

Fire resistant materials offer a high level of protection against fire hazards because they will not catch fire under normal oxygen pressure levels. Owing to their longevity they are also more expensive than the treated fabrics discussed in the next section.

The underlying mechanism used to create fire resistant fabrics is a blend of oxidized fibers that carbonize (char, in other words) and then expand, eliminating any oxygen content within the fabric (thus removing one leg of the fire triangle).

This process also provides a higher Thermal Protective Performance (TPP) index.

What is TPP?

It’s a way to measure a fabric’s thermal performance when exposed to convective or radiant heat (typically the kinds that occur during a fire). A TPP rating is a standardized number that breaks down to the number of seconds needed for a person to suffer second-degree burns from exposure to a fixed source of thermal energy.

Treated FR fabrics

The term “flame retardant” subsumes a diverse group of chemicals added to manufactured materials (such as plastics and textiles) and to surface finishes and coatings.

Flame retardants are activated by the presence of an ignition source. They are designed to prevent or slow further ignition (and do so using a variety of physical and chemical methods).

The mechanisms used to achieve flame retardancy are as follows:

Endothermic degradation

Exposure to high temperatures can cause endothermic breakdown of some compounds. This reaction removes heat from the substrate, which, of course, results in the material cooling.

Thermal shielding

This process stops flames from spreading by creating a thermal insulation barrier between the already burned parts of the material and those still intact.

Dilution of gas phase

Gases like carbon dioxide that are produced by the thermal degradation of certain materials dilute combustible gases, lowering their and oxygen partial pressures, and slowing their reaction rate.

We again return to our fire triangle (or, further down the line, the more accurate, expanded version, the fire tetrahedron, which adds the ingredient of chemical chain-reaction).

Particularly noteworthy here is that these materials (plus chemicals) are by their nature totally different from the fire-resistant version that is built from the ground up to be unable to catch fire.

But it does bring a welcome addition to the family. It opens the door to user-friendly and comfortable materials (such as cotton and other familiar fabrics) so that wearing it for extended periods is much more enjoyable and beneficial.

Where are the limitations of FR clothing?

As mentioned in the previous section, there exists a measurement of garment performance during exposure to an open flame.

In the 1986 revision of NFPA 1971, a new method of measuring thermal protection was introduced and a minimum thermal protective performance (TPP) rating was established.

It is important to remember, however, that the only way to increase a garment’s TPP rating is to add more insulation, usually by specifying heavier material components. The question that must be asked is whether the added seconds of protection gained in the event of a flashover environment is really a good trade-off against today's lighter-weight systems and higher Total Heat Loss (THL) values.

THL and TPP tests are both conducted on all three layers of clothing, treating them as but a single layer . This is necessary because it’s not possible to obtain a valid result by taking the values of one layer and merging them with the values of another layer.

Learn more about FR garments tests in this video from WorkriteFR.

What’s the difference?

- TPP (Thermal Protective Performance)—thermal insulation

Thicker/heavier = higher TPP (Protection)- THL (Total Heat Loss)—breathability

Lighter/thinner garment = higher THL (Comfort)

There is, in most systems, an important inverse relationship between TPP and THL. The optimum values for each are needed to achieve both comfort and protection. But, generally, as TPP goes up THL comes down, and as THL goes up TPP comes down. The goal, therefore, is to balance the two values.

A bulky system does not let you effectively move around, thus compromising your mobility is not a good system for operators.

The tradeoff between a few seconds in a high intensity scenario does not usually outweigh the costs of the 99.999% of the time you are in normal conditions.

The TPP ratings of garments are a crucial factor. Naturally, we’re always looking to optimize the benefits versus costs so that we still can provide optimal results.

Prolonged exposure to heat does definitely take its toll and cannot be easily prevented, even if the garment itself is fireproof and won’t catch on fire.

In these types of scenarios it’s important to understand the two different aspects of one’s protection in these kind of situations.

- The first being active protection. Active protection involves the individuals reaction to a threat, moving out of the way to get some cover.

- The second being passive protection. Passive protection means that the focus is put on the PPE’s (Personal Protective Equipment) physical or chemical capabilities to provide protection. This is where the FR garments shine.

Both of these are a vital part of the operators ability of getting out safely with minimal or preferably no injuries.

No-Melt/No-Drip: How does it compare?

A few words to debunk the myths surrounding this topic.

No Melt/No Drip is a feature exclusive to CORDURA® nylon.

NOT TRUE. It can be achieved by combining fibres that melt and drip with a quantity of natural fibres sufficient to absorb the melting material.

No Melt/No Drip has flame-retardant properties.

NOT TRUE. It’s not even slightly flame-retardant. It won’t protect your body against the fatal consequences of flames and/or heat-impact.

Learn more about No-Melt/No-Drip garments in this blog post here.

What is pyroshell™ technology?

For a long time now we’ve been intrigued with the flame-retardant technology developed by Schoeller.

One of the reasons for our interest in it is that the anatomic fit and comfort of the garments we make are for us a top priority. We did not want to compromise either fit or comfort by offering clunky garments ill-suited for ops where you, the wearer, will of necessity be moving about quite a bit.

So in fact the possibilities to create still comfortable flame retardant clothing supports the active protection

Another reason we are partial to Schoeller technology is that it does not consist of inherently flame-resistant fibres.

What is a non-inherently flame resistant fibre?

An inherently flame-resistant fibre is one that incorporates flame-resistance into its chemical structure. In plain words, that simply means the fibre is of its own accord able to extinguish a flame that hits its surface. This flame-snuffing capacity is the result of a chemical reaction triggered by the heat of the fire to which the fibre is exposed during a certain amount of time.

It’s a technology that transforms materials which normally will burn when exposed to fire into materials that don’t. It yields a FR garment that exceeds expectations.

Tested in EMPA: “Thermo Man testing”. We achieved outstanding results when we tested our Striker FR BDU made out of pyroshell with a 3-second flash-over on a Thermo Man test dummy wearing WoolPower 200 underwear.

The pyroshell™ had seemingly excellent heat- and flame-protection properties, but we did not quite understand it’s underlying principles when seeing it in action.

At the time it seemed improbable that this fabric did not have as its basis a non-inherently FR fabric. Furthermore the garments still had all the awesome functional elements, like stretch properties and lack of bulkiness.

In our talks with developers we learned what makes pyroshell™ such a breakthrough technology, one that really did reimagine the way we conceive of FR systems.

What Schoeller has done is simply glue together two materials—conventional nylon and a material with stretch properties. And “just” by gluing them together they became flame retardant.

This was ingenious. It took a fabric (nylon) susceptible in normal conditions to excessive heat and turned it into something quite remarkable.

But it as we digged deeper into the technology, we learned that it it is the middle adhesive layer that most fully shows-off Schoeller’s innovation. There you find that graphite has been incorporated. It is the presence of graphite in this layer that provides the FR qualities we desire.

What is graphite?

Graphite is simply carbon in crystalline form with its atoms arranged in a hexagonal structure. This makes graphite a good conductor of heat and electricity.

OK, that’s a cool fact, but you might wonder how this comes together to create the FR combat pants? When exposed to heat, the graphite swells through the fabric and envelops the material in a non-burning layer that tshields those otherwise flammable fibres from direct exposure to heat or flames. In so doing, those materials are prevented from catching on fire.

Furthermore, this eliminates the need to hassle with available colours, minimum order quantities, et cetera, of the inherent FR fibers, that are not checking our boxes when it comes down to our preferences and the requirements of our customers.

Abrasion resistance and piling are also a problem with classic flame resistant fibers. A big one, in fact, because the inherent FR fibres have inferior performance when it comes to durability.

Thanks to new flame-retardant technology—such as pyroshell™ by Schoeller, which we use in our Striker FR system—we have access to truly excellent flame protection. This technology combines flame protection with heat insulation and makes no compromises with regard to wearer comfort or other fabric properties.

You can take a look at our Striker FR Combat Uniform in this video, hosted by Armin, our Head of Development.

Please note: This product is available for government personnel only. For more info, contact us here.

Vous en voulez toujours plus ?