The latest material used in the US Improved Hot Weather Combat Uniform - IHWCU for short is said to be a game-changer. But how does it stack to regular NyCo ripstop? In this post, we share more insight into the newest hot weather material.

In this blog post:

Introduction

We’ve already extensively talked about NyCo in this post. The progression of synthetic Nylon created a high-strength fibre that worked exceptionally well when paired with the properties of cotton.

The material joins the best of both worlds and creates a fabric that’s high in strength, durable but breathable, and comfortable to wear.

On the surface, it seems that CORDURA® NyCo Extreme takes what's already a great functional fabric and takes it to another level. Two steps forward (or in this case four steps forward) and none back.

New fibre, new leaps in performance

CORDURA® fabric simplifies its extraordinary qualities in easy to understand categories and sets the bar with “CORDURA® NYCO fabric US Mil-Spec MIL-DTL-44436B”

*compared to US Mil-Spec for NYCO fabric

- 17% Lighter*

- Up to 3x higher tearing strength*

- Up to 10x more breathable*

- Up to 35% faster drying time*

So if you get what they managed to pull off here is quite the feat of engineering. Lighter yet more durable. Better breathability yet a higher percentage of Nylon (Cotton is what brings breathability to a fabric).

At the base of it all is the new fiber codename T420HT. And with it came one of the largest leaps in Nylon technology since the 1960s.

Two years of extensive research went into improving the new 6.6 nylon fibre previously used. Just from looking at the name (T420HT) you see some red threads. The only two letters that differentiate it from the previous version is the HT added at the end, which stands for High Tenancy.

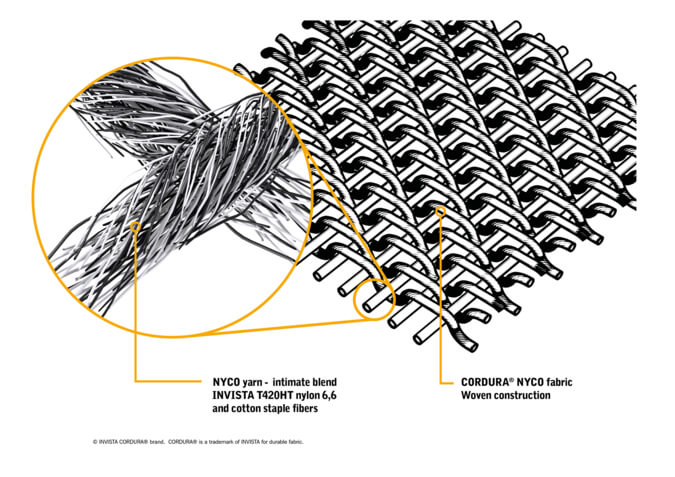

As this graphic confirms, the new CORDURA® NyCo Extreme remains an intimate blend of Cotton and Nylon. Intimate blend put simply is a mixture of two materials into one yarn, to maximize the benefits of both materials and mask the “not so good” qualities.

Image source: CORDURA® brand

What this means is the actual yarn remains similar to that found previously in other NyCo fabrics. What is different however is the percentage of Nylon found in the blend, increasing from 50% to 57%.

In the Future of NyCo materials section, we briefly mentioned that increasing the percentage of the blend ratio was one way to improve the performance of the fabric. But this is a thin line to walk in tactical space. Increasing the percentage of Nylon decreases the no-melt/no-drip properties.

The other potential favorable part of the equation when improving a fabric was to switch to a more technical yarn construction, which could improve the material's properties significantly.

Altho this does bring an upside, meaning we could expect another jump in performance in the near future by implementation of core-spun or covered-spun NyCo yarns.

IHWCU lab and in-field testing

Despite the big boom of the new material, it’s difficult to get hard data on it. On the one hand, you have the UK Royal Marines and US Military’s IHWCU adopting the new fabric in their uniforms. On the other, you have a set of measurements done by CORDURA® brand.

Luckily we stumbled upon an “Approved for release to the public” research paper from the known US Army Natick Research Institute.

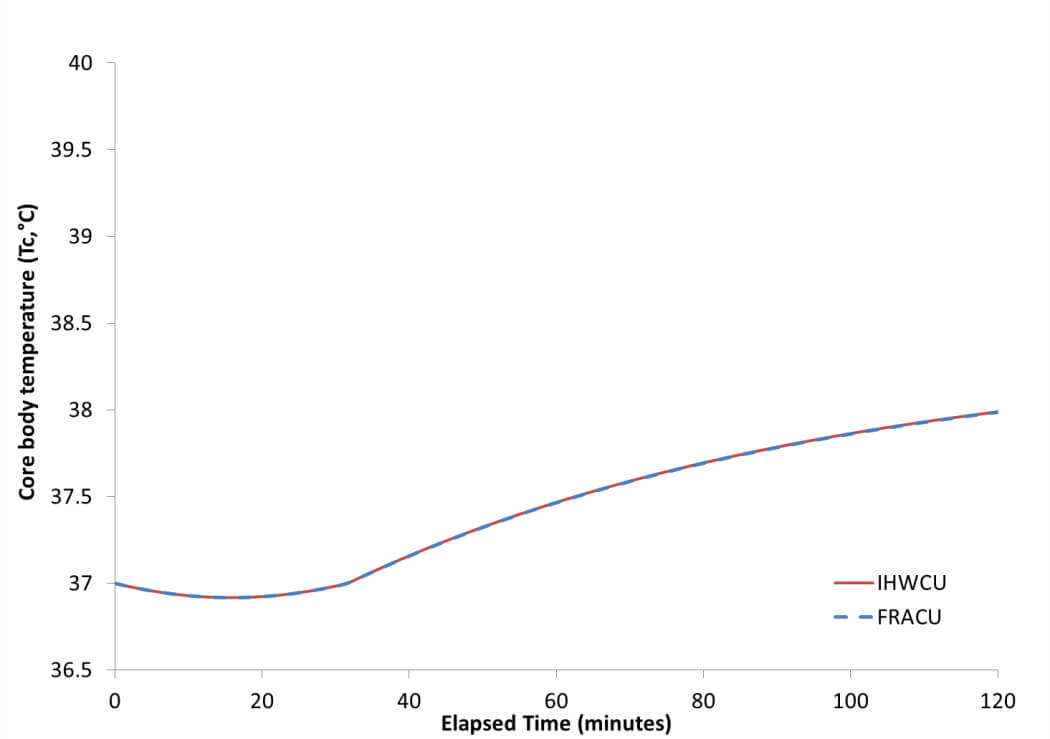

In the test, they compare the standard-issue Fire Resistant Army Combat Uniform or FRACU to the new IHWCU made from CORDURA® NyCo Extreme. They measure and model data of thermal performance, breathability, and evaporation potential.

Image source: Research Institute of Environmental Medicine

For reference, the FRACU is made from DEFENDER M 680 woven fabric made from a mixture of Lenzing FR Rayon, Para-Aramid & Nylon.

The results were interesting, to say the least as they show little difference between the two BDUs. To summarize the paper the differences in human perception between the two are negligible. That is, except for the actual weight of the uniforms, the IHWCU is lighter than the FRACU.

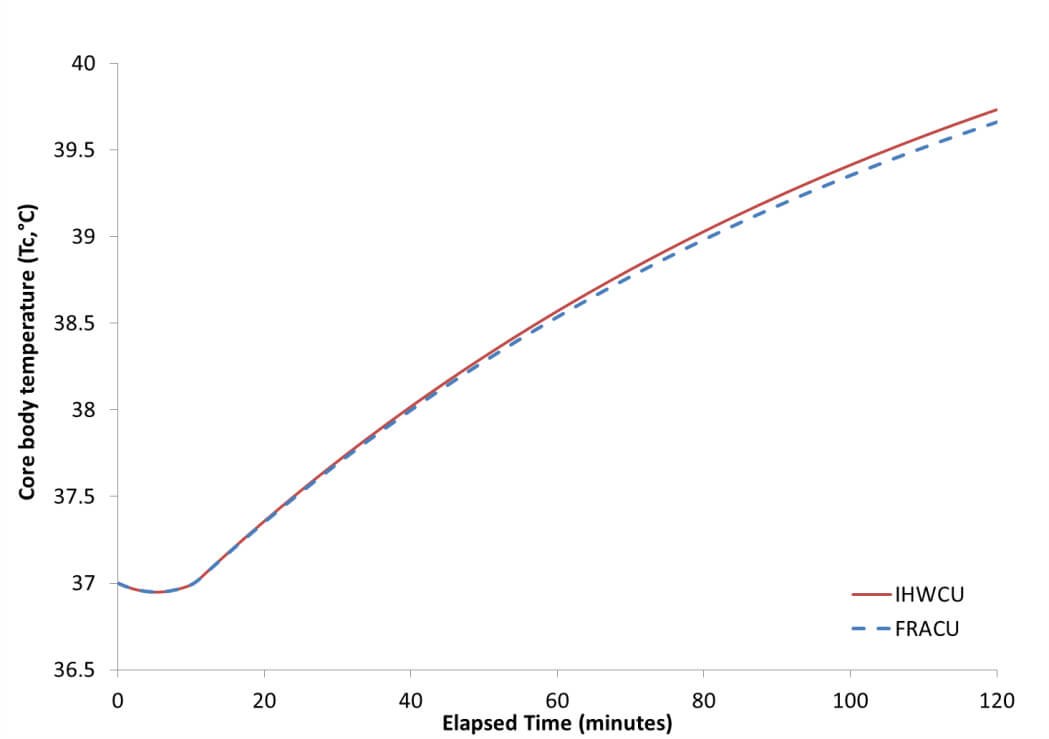

The most interesting modeling done here was the predicted body temperature without load (top) and with a 34kg load (bottom).

Image source: Research Institute of Environmental Medicine

A disclaimer present in the outro of this research is that despite lab measurements and models this test requires in-field data. Especially in the tactical field, perfect environment lab results show only numbers and are not indicative of performance in the field.

The in-field testing did of course take place for 18 months starting in 2016 projecting approval of the new selected uniform by 2018. The testing took place in Hawaii and reportedly used 8 different ACUs. Amongst them were CORDURA® NyCo (50/50) and NyCo Extreme (57/43) ripstop, which were a favorite amongst the testing operators.

Two quotes from a U.S. Sgt. paint perhaps the clearest image “Some felt like a regular uniform. Some felt like you were putting on pajamas”, and “I’ve taken it (CORDURA® NyCo Extreme ACU) through the Congo, through a harsh obstacle course. I put it in every situation; the uniform came out unscathed. I didn’t feel like I was too hot or too cold. I’ve slept in that uniform. Overall it’s just comfortable wear,” he said.

The new and lighter material shaved the weight (by 500g or 1 pound) and was ultimately selected in 2018 by the US Military as the optimal combination of light, durable, moisture-wicking ACU.

What does it mean for the tactical space?

Improvements in materials mean direct benefits to tactical clothing. A higher-performing material without reduced durability that lowers weight. Pluses in every category.

However, just changing the material is a small piece of the equation. You have to recognize other categories:

- Correct fit of the garment

- Air permeability or air circulation

- Re-drying

- Functional elements

If you’re interested in looking further into the topic of weight in tactical clothing you can read our article “Does less weight equal more comfort” here.

What we’ve swept under the rug in the previous segment was that alongside fabric swap, the ACU’s underwent other changes, new cuts, ventilation meshes, removing non-essential functional elements.

A trend you can find in our latest Striker ULT Combat Pants and P-40 Gen.2 Shorts. The material change alone is not enough to make a product suitable for hot weather

The final verdict

It’s unclear how CORDURA® brand managed to boost its existing yarns to this new level of performance. But, manage it they did.

Speaking from personal experience, the new material does indeed have a better feel to it. It’s lighter and airier without giving you the sense of being flimsy. In other words, it won’t make you feel like you need to exercise great care with it (such as avoiding contact with bushes, barbs, or protruding objects). But we’re judging it from an “unfair standpoint” by comparing it to a new model of tactical and combat pants with improved cut and new functions that boost the level of comfort.

Browse UF PRO gear using CORDURA® NyCo Extreme